To ensure the safe arrival of your products,you may have noticed common packaging guidelines for protecting the products of the shipping process. Some tips are unique to certain kinds of goods but all of these ultimately ensure the safety of the goods.

1. Use high quality corrugated paperboard boxes

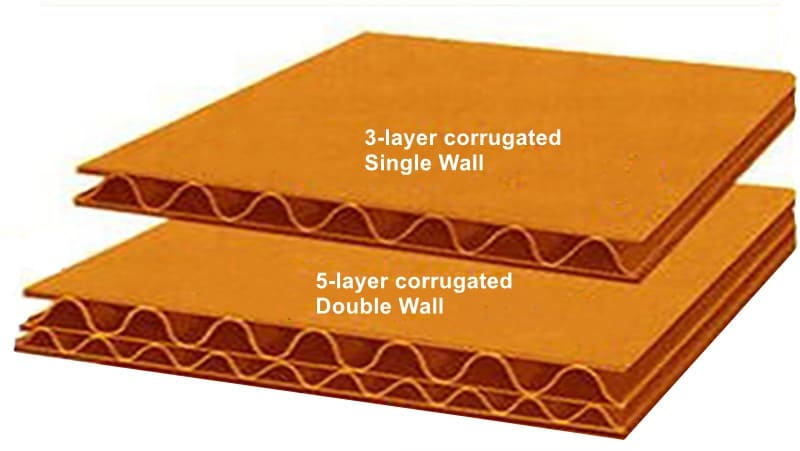

Opt for sturdy boxes with appropriate weight capacities. Inner boxes should typically be 3-layer corrugated, while outer cartons should be 5-layer corrugated for added protection.

2. Don’t exceed the weight limit of the box

Avoid overloading boxes, as this can increase the risk of damage during handling. Also, refrain from reusing old boxes, as they may lose their structural integrity over time.

3. Leave no empty space

Under-filled boxes can collapse if too much weight is on top of it. Filling the box up to the brim without overflowing helps increase its ability to withstand forces coming from top.

4. Wrap individual items

Wrap each product separately to shield them from potential damage during shipping.

5. Use appropriate packing materials

Use specialized packing materials for fragile items to maintain their integrity throughout the shipping process.

6. Seal the package well

Seal packages securely with ample tape to ensure the goods remain intact throughout th shipping.

7. Label the shipment appropriately

Ensure shipments are appropriately labeled with product information and handling instructions. Complimentary product labels can be provided upon request, including markings for inner boxes and outer cartons.

8. Include a silica gel if your product is sensitive to moisture

Include silica gel packs in moisture-sensitive products to mitigate the risk of damage during transit. Variations in humidity levels across different shipping locations underscore the importance of safeguarding products from moisture-related issues.

By adhering to these packaging guidelines, you can enhance the protection of your products and minimize the risk of damage during shipping, ensuring customer satisfaction worldwide.