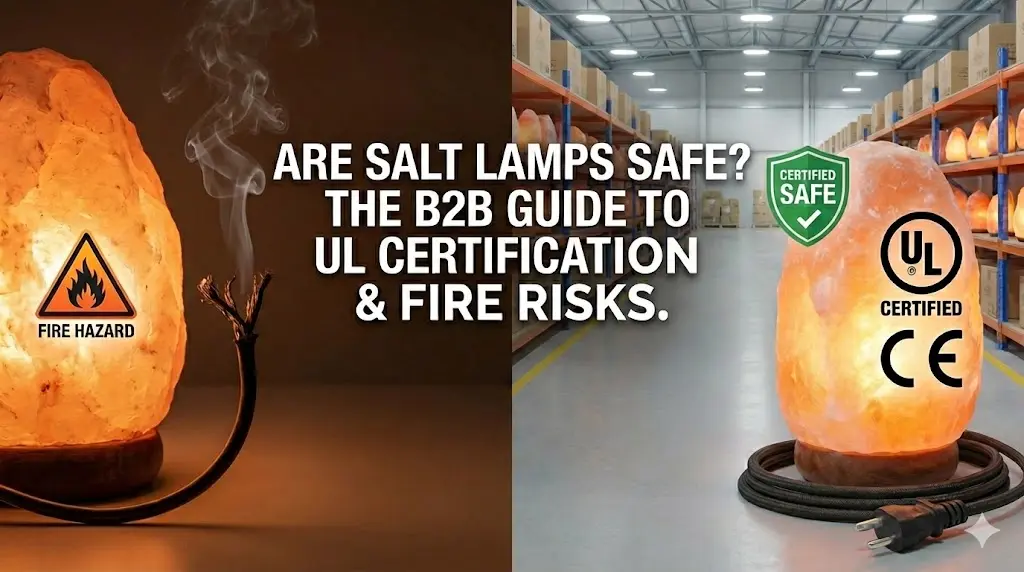

Fire risks in the salt lamp industry are driven by electrical failure rather than the mineral block, a reality made starkly clear when the CPSC recalled 80,000 Lumiere units in 2017 due to overheating dimmer switches. Retailers selling inventory without verified electrical certifications face direct exposure to negligence lawsuits and product seizures, as hygroscopic salt combined with substandard wiring creates a proven mechanism for short circuits and thermal runaway.

This guide outlines the critical compliance frameworks required for legal distribution, specifically detailing the fire mitigation tests within UL STD.962 for the US and CAN/CSA C22.2 No. 250.4 for Canada. We breakdown the technical failure points of counterfeit Model 303 switches and examine how compliant suppliers like Ewoodarts utilize 16-gauge wiring and ISO 9001 protocols to guarantee safety during 24/7 operation.

The Reality of Fire Risks

Fire risks stem from electrical failures—specifically defective dimmers and uncertified wiring—rather than the non-flammable salt block itself.

Source of Ignition: Electrical Components vs. Salt Properties

Salt blocks are non-flammable. The fire risk comes entirely from the electrical components housed within the lamp. Because salt is hygroscopic, it absorbs ambient moisture. If the lamp uses uncertified wiring, this moisture corrodes the copper and degrades insulation, leading to short circuits. Counterfeit UL marks on pendant cords frequently mask poor insulation that cannot withstand this moisture exposure.

Defective switches represent a proven failure mode. The 2017 CPSC recall of 80,000 Lumiere units was caused specifically by dimmer switches that overheated and melted, not the lamp body. You must isolate the risk to the cord assembly, not the mineral.

Thermal Runaway Risks and Wattage Thresholds

Safe operation requires strict adherence to wattage limits. You must run these lamps with bulbs between 15W and 25W. Using a bulb exceeding 25W triggers thermal runaway, raising surface temperatures near ignition thresholds because the salt cannot dissipate the heat fast enough. Certified assemblies undergo specific heat dissipation tests to validate 24/7 usage.

- UL STD.962: The US standard for household lamps that validates fire risk mitigation.

- CAN/CSA C22.2 No. 250.4: Canadian certification ensuring safety against fire and shock hazards.

- CE 2014/35/EU: European directive mandating compliance for low voltage safety.

Understanding UL, CE, UKCA Standards

Regional compliance dictates market access. UL verifies US electrical safety, CE covers EU low-voltage mandates, and UKCA applies equivalent testing standards for Great Britain.

| Region | Standard / Directive | Core Technical Focus |

|---|---|---|

| United States | UL STD.962 & UL 153 | Fire mitigation, fixture stability, wiring insulation |

| European Union | CE (2014/35/EU) | Low Voltage Directive (50-1000V AC), shock protection |

| Canada | CAN/CSA C22.2 No. 250.4 | Grounding, overload protection, thermal hazards |

| Great Britain | UKCA | Mirrors EU safety standards for electrical goods |

Decoding Safety Marks: UL, CE, and UKCA

Regulatory bodies operate on distinct jurisdictional lines. Manufacturers cannot rely on a single certification for global distribution. You need to verify the correct mark for your specific export destination to avoid customs seizures or liability lawsuits.

- UL (Underwriters Laboratories): The operational prerequisite for the US market. Labs conduct destructive sample testing on electrical components to catch overheating issues and fire risks before mass production.

- CE (Conformité Européenne): A mandatory conformity marking for the European Economic Area (EEA). It signals strict adherence to health, safety, and environmental protection laws, specifically regarding voltage regulation.

- UKCA (UK Conformity Assessed): The post-Brexit regulatory framework for Great Britain. It mirrors EU safety standards, requiring specific conformity assessments for low-voltage and EMC testing.

Specific Standards & Testing Protocols

Compliance requires meeting exact technical codes, not just slapping a sticker on a box. Inspectors audit products against specific directives to ensure components like dimmer switches and insulation can withstand daily use.

- UL STD.962 & UL 153: These standards govern “Household Portable Lamps” and “Portable Electric Luminaires.” Testing focuses on fixture stability, wiring insulation, and switch durability. Be wary of counterfeit UL marks on “Model 303” pendant switches, which historically fail safety evaluations and pose fire risks.

- EU Directive 2014/35/EU: Known as the Low Voltage Directive, this governs electrical equipment operating between 50 and 1000V AC. It ensures consumer protection against electrical shock and thermal hazards.

- CAN/CSA C22.2 No. 250.4: The Canadian benchmark. It aligns with UL requirements to certify portable luminaires, focusing heavily on insulation, grounding, and overload protection.

Anatomy of a Safe Cord & Socket

Certified safety relies on polarized plugs (UL 498), 16-gauge wiring (UL 817), and double-layered PVC insulation (UL 2556) to prevent thermal overload and shock hazards.

| Component | Standard | Safe Specification | Risk of Failure |

|---|---|---|---|

| Internal Wiring | UL 817 | 16 AWG (Minimum) | Overheating / Melting |

| Plug Head | UL 498 | Polarized (Wide Neutral Blade) | Electrical Shock |

| Insulation | UL 1015 / UL 2556 | 1/32 Inch Double PVC | Short Circuits / Fire |

Plug Architecture & Connection Logic

The plug serves as the primary mechanical firewall between the grid and the device. Safe engineering focuses on the physical interface to prevent exposed conductors or reverse polarity.

- UL 498 Compliance: The attachment plug must pass strict blade retention tests. This prevents the metal blades from loosening or detaching inside the socket, which exposes live conductors.

- Polarized Design: UL 817 mandates a polarized plug with one wider prong (neutral). This forces the correct orientation, ensuring the lamp switch cuts the ‘hot’ wire rather than the neutral one. Without this, the socket remains live even when switched off.

- Dielectric Withstand: Connectors undergo high-voltage surge testing, typically 1,000 volts RMS. This verifies the material will not arc or break down during power spikes.

Wire Gauge & Insulation Standards

Cheap cords often utilize thin 18 or 20 AWG wires that create resistance and generate excess heat. A compliant assembly prioritizes copper thickness and jacket durability to manage thermal loads safely.

- Minimum Wire Gauge: Safe cords use at least 16 AWG wire (per UL 817). This thickness handles the current flow without significant temperature rise.

- Insulation Thickness: Wires require double insulation, typically 1/32 inch PVC adhering to UL 1015 standards. This thickness resists physical damage from pinching or furniture abrasion.

- Flame Resistance (UL 2556): The outer jacket undergoes vertical flame testing. If a short occurs, the material self-extinguishes immediately rather than acting as a fuel source for the fire.

Source Authentic Himalayan Salt Lamps Direct from the Factory

Why “Cheaper” Cords Fail

Cheap cords fail because counterfeit components and weak insulation cannot handle standard thermal loads, leading to overheating, arcing, and fire hazards.

Counterfeit Components and Insulation Breakdown

Low-cost assemblies often rely on “grey market” components that mimic safety standards without actually meeting them. The most dangerous shortcuts appear in the switch mechanisms and wire sheathing, where manufacturers bypass testing to cut costs.

- Switch Fraud: Factories frequently stamp counterfeit UL marks on Model 303 pendant switches (3A/120 VAC) that fail actual load testing.

- Dielectric Failure: Substandard insulation lacks the necessary dielectric strength, causing internal arcing and short-circuiting during operation.

- Material Degradation: Non-compliant plastics become brittle and crack, exposing live wiring and increasing shock risks.

Thermal Intolerance and Environmental Corrosion

Standard E12 bulbs (15-40W) generate significant heat inside the salt cavity. Uncertified cords lack the thermal tolerance to dissipate this heat, leading to plastic deformation. In 2017, the CPSC recalled approximately 83,900 Lumiere units after faulty dimmer switches overheated and ignited.

The environment compounds these material failures. Salt is hygroscopic and pulls moisture from the air. This moisture settles on exposed, non-UL metal contacts, causing rapid corrosion. Corroded contacts increase electrical resistance, which generates excess heat and creates a feedback loop that melts the switch housing.

How to Verify Certificates

Validate safety claims by cross-referencing the manufacturer’s file number in the UL Product iQ™ database and inspecting physical units for the holographic UL Listed mark.

Digital Validation via UL Product iQ™

The UL Product iQ™ database serves as the definitive record for authentication. Search using the manufacturer’s specific file number or certification number. A lack of search results indicates a fake or expired certificate. Do not rely on PDF certificates sent by email, as vendors can easily forge these.

- Status Check: Ensure the file status is “Active,” confirming the manufacturer undergoes unannounced field visits.

- Classification: Verify the product is “UL Listed” (finished product) rather than just “UL Recognized” (components only).

- Standard Match: Confirm the certification references UL STD.962, the standard for household electric lamps.

Physical Inspection & Labeling Compliance

Physical labels must verify the digital data. Counterfeiters often apply generic UL stickers to untested assemblies. Inspect the cord and socket for the official UL Listed mark, which usually appears as a holographic label or a specific black circle logo containing “UL.”

- Standard Codes: Look for UL STD.962 or CAN/CSA STD. C22.2 No. 250.4 (Canada) printed on the label.

- Wattage Limits: The label should mandate 15-25W bulbs to prevent thermal runaway.

- Component Markings: Check switches for independent certification marks.

High-risk components require scrutiny. The 2017 recall of 80,000 Lumiere units resulted from defective dimmer switches that overheated. Verify that the dimmer switch housing itself bears a safety mark, not just the plug. Cheap assemblies often use uncertified switches that fail under continuous use.

Final Thoughts

Cheap salt lamp cords save cents upfront but invite lawsuits and recalls later. Certified inventory is the only real insurance against fire liability and reputation damage.

Stop trusting PDFs and start inspecting physical plugs for the holographic UL mark. Mandate UL STD.962 compliance in every supplier contract immediately.

Experience the quality firsthand with our trial order – an easy way to test these high-margin products with just a $500 investment. Get in touch to start your trial order today!

Frequently Asked Questions

Do Himalayan salt lamps really catch fire?

Genuine salt blocks do not burn. Fire risks come entirely from cheap, uncertified electrical components. In 2017, the CPSC recalled 80,000 Lumiere brand units because faulty dimmer switches overheated and ignited. To ensure safety, verify the lamp uses UL-certified cords and strictly adheres to the 15-25W bulb limit.

What does ‘UL Listed’ actually mean?

UL Listed means the entire lamp assembly—not just the plug or cord—passed Underwriters Laboratories safety tests (specifically UL STD 962). This certification verifies the product’s insulation, grounding, and ability to resist fire under load. Without this mark on the base or assembly, you are trusting untested wiring.

Is it safe to leave a salt lamp on 24/7?

Yes, provided the lamp is UL-certified. Manufacturers actually recommend continuous operation because the heat prevents the hygroscopic salt from absorbing moisture and “sweating” onto furniture. Ensure you use low-wattage bulbs (15-25W) to prevent the fixture from overheating during prolonged use.

Are salt lamps safe for pets?

No. These lamps pose a severe risk of sodium poisoning to cats and dogs. Pets are often attracted to the salty taste and will lick the lamp repeatedly. This leads to excessive sodium intake, vomiting, seizures, and potentially death. You must keep these strictly out of reach of animals.

Do I need insurance compliance for these lamps?

Retailers must ensure inventory meets UL STD.962 or equivalent ETL/CSA standards to satisfy liability insurance requirements. Selling uncertified electrical products exposes your business to significant financial risk in the event of an electrical fire or consumer injury.

Why do the bulbs in salt lamps blow so often?

Bulbs usually blow due to incorrect wattage or moisture damage. Using a bulb higher than 15W in a small lamp traps excessive heat, while high humidity causes salt to melt into the socket and short the electrical connection. Use 15W E12 candelabra bulbs and keep the lamp in a dry environment to fix this.