For retailers expanding in the home décor or craft market, sourcing wholesale wooden birds directly from manufacturers can redefine both cost and quality. When intermediaries add 5–10% markups and limit visibility over material origins, direct factory access ensures transparency and sharper margins. With FSC‑verified basswood and repurposed Java wood leading the industry for sustainable carving, factories can guarantee chemical‑free products that meet retail and eco‑compliance standards.

This guide explains how direct sourcing works—covering certifications like FSC and PEFC, pricing tiers from $0.22 bulk blanks to $200 artisan pieces, and the production advantages of basswood. You’ll learn how wholesale wooden birds move from raw wood selection to packaging, and how retailers can customize shapes, finishes, and logistics terms to match their brand and budget.

Why Sourcing Direct Matters

Sourcing directly from certified manufacturers eliminates intermediary costs, provides better quality control, and ensures sustainable, chemical-free materials like FSC-verified basswood or pinewood are used for bird products.

| Certification / Term | Purpose or Impact | Relevance to Direct Sourcing |

|---|---|---|

| FSC Chain of Custody | Verifies wood originates from responsibly managed forests. | Ensures consistent sustainable sourcing control at manufacturer level. |

| PEFC Certification | Confirms sustainable management of forest-based materials. | Alternative documentation for sustainability audits. |

| FOB / FCA Incoterms | Used for bulk shipments directly from factory ports. | Supports lower cost structures for large retailers bypassing intermediaries. |

| DDP / DAP Incoterms | Factory handles delivery and duties for small importers. | Simplifies direct sourcing for smaller retailers. |

| 100% Chemical-Free Wood | Eliminates chemical finishes and coatings on natural wood. | Verifiable only through direct manufacturer contact. |

| Java Wood (Coffee Byproduct) | Repurposed from unproductive coffee trees; supports regenerative farming. | Provides durable, waste-free perch material for sustainable sourcing. |

Direct Sourcing and Its Impact on Quality and Cost

Buying from certified wooden bird product manufacturers removes 5–10% of intermediary agent commissions, which directly improves retail margins. Retailers receive exact factory pricing and transparent control over raw material sourcing, helping align quality standards across regions.

Working directly with the manufacturer gives buyers flexibility to confirm wood treatment methods, ensuring every birdhouse or perch remains chemical-free. It also shortens communication lines, allowing faster design approval, prototype evaluation, and production adjustments, all of which reduce turnaround time on custom wooden bird products.

Sustainability and Supply Chain Control

FSC Chain of Custody and PEFC documentation track sustainable wood from forest to finished bird accessory. These verifications strengthen the manufacturer’s environmental compliance and assure end buyers of authenticity. They also minimize risks associated with uncertified third-party suppliers.

Retailers can choose appropriate Incoterms based on their shipment size. Larger companies often select FOB or FCA for cost efficiency and port control, while smaller buyers choose DDP or DAP for full-service delivery options. These terms depend on whether customs handling and transport should be managed by the buyer or supplier.

Direct partnerships also help maintain globally recognized compliance such as BSCI and ISO9001 production standards. This ensures consistent quality monitoring and sustainable manufacturing throughout the supply chain.

Research Summary

European retail data shows a steady trend toward direct sourcing of wooden bird items to eliminate hidden agent margins, enhance customization capacity, and improve delivery speed. The shift enables real-time feedback between buyer and manufacturer, boosting product innovation.

Direct sourcing benefits both new and established businesses. Novices gain supplier reliability for chemical-free materials, while seasoned buyers benefit from favorable FOB pricing structures and shorter logistics routes from Vietnam or India. Although specific ASTM or ISO tests for wooden birds do not yet exist, recognized sustainability labels such as FSC and PEFC remain critical trade verifications.

The Basswood Advantage

Basswood offers an ideal balance between light weight, workability, and dimensional stability. Its fine texture and consistent grain allow artisans to achieve smooth detail with minimal tool wear, making it the material of choice for carved bird production.

Material Qualities and Workability

Basswood’s soft density of about 26 lbs/ft³ makes it simple to carve using hand. This low hardness supports rapid shaping without splintering, which is valuable during high-volume wooden bird fabrication.

The fine, even grain produces smooth edges and consistent surfaces, so sanding and tool maintenance are reduced throughout production. Such uniformity across batches helps scale operations while keeping finish quality predictable.

It also glues and finishes reliably, supporting stable joints and coatings during assembly. These characteristics make basswood practical for automated carving systems and for maintaining a uniform aesthetic across wholesale runs.

Technical Data and Manufacturing Advantages

Dimensional stability after drying is strong, supported by volumetric shrinkage near 15.8%. With proper kiln control, waste from warping and cracking stays low across machining stages, preserving yield for scaled manufacturing lines.

The specific gravity range of 0.32–0.42 keeps the material light enough to reduce shipping costs while still supporting durable assembly. Because basswood is rated non‑durable to rot, sealing or coating must happen immediately after carving to guard against moisture absorption during storage or transport.

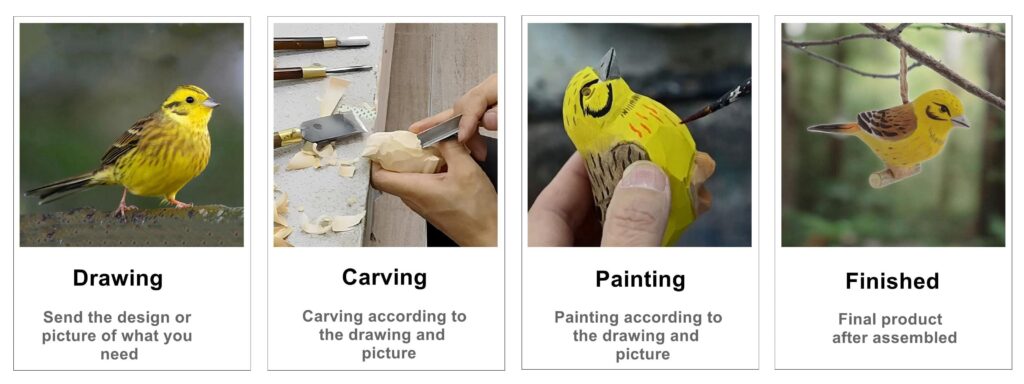

Our Carving Process

The carving process starts with soft, fine-grain woods like basswood that are cut, shaped, and refined through multiple tool stages, sanding, and detailing to craft lifelike wooden birds built for quality and scale.

Creating each wooden bird begins with a focus on material selection, grain pattern, and structural strengths suited for finely detailed carving. Every step, from rough cutting to final sanding, supports both artistic precision and wholesale-level consistency.

Selecting and Preparing the Wood

Primary woods such as basswood, pinewood and birchwood are chosen for their soft texture and even grain. These materials allow artisans to achieve sharp details without splitting or dulling tools too quickly. Each blank is inspected for knots, cracks, or irregular grain direction to guarantee a balanced carving surface.

Wood blocks between 35 mm and 50 mm thick are selected for body work. This range provides the necessary volume to create smooth contours and rounded bird forms without risking fragility during shaping. The wood is lightly air-dried to maintain flexibility and avoid surface tearing during cuts.

Shaping, Detailing, and Finishing

Once the design outline is traced, shaping begins with whittling knives, detail knives, chisels, gouges, V-tools, and the Mora #120 knife for controlled rounding. These tools manage both mass removal and fine texturing, defining the bird’s symmetry, head tilt, and feather layers piece by piece.

Research Overview

Research shows that softwoods like basswood are optimal for bird carving due to their blend of strength and finesse. Typical blank thickness ranges from 35 mm for small species to 50 mm for larger birds. Carvers usually rough out silhouettes using bandsaws or carving knives, then refine shape and volume through guided cuts with whittling or V-tools aimed at maintaining balance and proportion in each section.

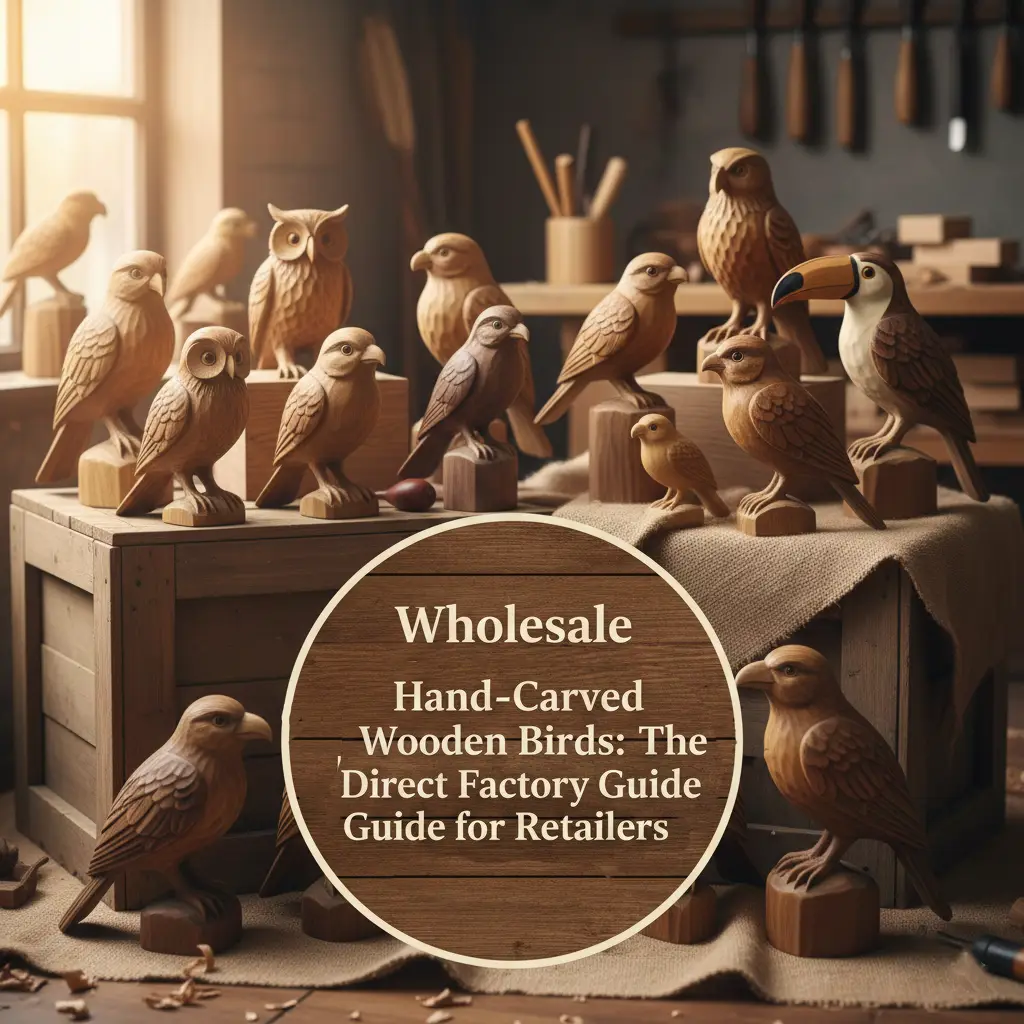

Bring Nature’s Art to Life — Wholesale Hand-Carved Wooden Birds

Popular Bird Species (Cardinals, Chickadees)

Cardinals and chickadees are highly requested wooden bird models due to their distinct shapes, bright colors, and symbolic appeal. They are carved or laser-cut to meet craft, decor, and retail needs while maintaining practical sizes and durable materials.

Design Appeal of Cardinals and Chickadees

Cardinals are recognized for their rich red tone and clean silhouette that makes them visually striking in displays. The simplicity of their outline offers easy adaptation for both 2D cutouts and fully carved figurines, giving artisans flexibility across laser-cut and hand-carved product lines.

Chickadees, on the other hand, bring a friendly and natural charm that fits well into rustic, winter, and woodland settings. Their round body shape and contrasting plumage help small decor items look lively while maintaining an approachable design language that appeals to a wide audience in seasonal or everyday home decor.

Dimensions, Materials, and Production Styles

Typical dimensions for wooden bird models range from about 5–15 cm in height and 0.25–0.32 cm in thickness. These measurements balance portability, efficient wood use, and enough surface area for painting or finishing. Small items like a 6-inch (15 cm) cardinal cutout or carved bird figurine conform well to retail packaging and bulk display units.

Material selection differs by production style. Laser-cut models commonly use Baltic birch with a 1/8 inch (0.32 cm) cut, favored for its stability and clean edges in scalable production runs. In contrast, hand-carved variants often rely on solid basswood or generic hardwoods that support texture-rich carving, allowing unique variations in each piece. While laser-cutting ensures repeatability for large-volume orders, hand-carving adds tactile depth suited for artisan collections where visual uniqueness matters.

Research data indicates that these compact and lightweight designs reduce shipping costs and optimize wood yield during manufacturing. Even without fixed industrial standards, consistent cuts and finishes are achieved through process refinement—either digital precision for laser-cut designs or skilled craftsmanship for hand-shaped work. Baltic birch remains the preferred stock for wholesale cutout forms due to its balance of rigidity and lightness, while solid wood varieties cater to gift and decor markets where handmade aesthetics take priority.

Packaging for Retail

Retail packaging combines protective design, compliance with international wood packaging standards, and aesthetic presentation to ensure safe transport and strong market presence for wooden bird products.

Protective and Retail-Ready Design

Each carved wooden bird is individually wrapped using polybags or paper, often including desiccants to control moisture during storage and shipping. This approach prevents surface damage, staining, or cracking from humidity changes.

Packaging is optimized with 12 pieces per inner box, carefully aligned to achieve a dense load without abrasion between items. This configuration also makes it easier to repackage for retail sales or small orders.

Color boxes serve as the retail presentation packaging. Once unboxed, the products can be placed directly on store shelves without repacking, balancing both functional protection and consumer appeal.

Compliance, Testing, and Shipping Efficiency

The basswood used for carving undergoes kiln drying to achieve 8–12% moisture content. After packaging, completed cartons are subjected to a 48-hour humidity test to confirm they maintain internal dryness and dimensional stability during storage and transport.

Master cartons consist of 5-ply corrugated fiberboard, each containing 240 pieces organized in 20 inner boxes. This carton strength supports long-distance stacking while keeping carton deformation under control.

A final inspection follows AQL 2.5 quality levels, covering structural integrity, labeling, moisture, and finish. Certification systems such as FSC, ISO 9001, and BSCI authenticate both the responsible sourcing and safe handling of each shipment, guaranteeing readiness for export retail standards.

Pricing & Margins

Pricing in the wooden bird segment depends on craftsmanship and production volume. Hand-carved birds retail from $60 to $200 with higher artisan costs, while unfinished blanks sell for under $5 per unit for volume buyers.

| Segment | Wholesale/Production Cost | Retail/Resale Price Range |

|---|---|---|

| Hand-carved wooden birds | $200–$300 per sample + $7–$10/kg shipping | $60–$200 retail depending on craftsmanship and material |

| Craft/DIY wooden blanks | $0.22–$5 per unit (bulk) | Typically under $20 retail for plain or DIY pieces |

Cost Components and Pricing Models

The pricing of wholesale wooden birds is shaped by material quality, artisan labor, and logistics. Sample production for custom designs often costs $200–$300 per unit, particularly when the buyer requests exclusive patterns or species-specific birds. Shipping adds another $7–$10 per kilogram depending on the destination and carrier agreement. These factors combine to establish a base price before markups or retail margins.

Retail sale values can vary widely—from under $20 for basic craft birds to more than $200 for large, polished sculptures. Premium hand-carved goods use a cost‑plus pricing model, linking final price to the type of wood (such as suar, hibiscus, or mahogany) and artisan craftsmanship. This structure rewards quality and uniqueness rather than sheer production volume.

Margin Ranges and Order Economics

Margin potential changes significantly with order size and buyer profile. Bulk buyers sourcing wood blanks at $0.22–$5 per unit can achieve competitive pricing for high-volume retail or craft distribution. These low selling prices support small but consistent margins spread across hundreds of units.

In contrast, hand-carved collectors’ models priced between $60–$200 permit strong markups due to limited production runs and artistry. Container-based wholesale orders, typically around 40 cubic meters or more, represent substantial inventory commitments. This procurement scale enables reduced per‑unit transport cost but requires higher upfront investment. Overall, margins range from slim for bulk craft blanks to robust for premium carvings, reflecting the trade‑off between mass access and artisanal value.

Customization Options

Jilin Ever Creation offers custom shape, color, material, and packaging options through its OEM & ODM services, enabling retailers and brands to align product appearance, labeling, and presentation with their identity and market needs.

Design and Material Choices

Clients can define the overall shape and dimensions of each wooden bird, whether for ornamental display, craft kits, or retail gift assortments. Jilin Ever Creation supports modifications to contours, wing spans, and base profiles while maintaining balance and structural integrity. Premium basswood is the primary materials, selected for their uniform grain and carving stability.

Custom visual finishes include carved or etched detailing, multi-layer painted color palettes, and patterned surface artwork produced with assistance from the in-house R&D team. This process ensures that each design accurately matches brand themes while allowing consistent reproduction across batch orders. Decorative options like stencils or texture overlays can also be integrated for more distinctive retail appeal.

Technical Specifications and Packaging Customization

The minimum order quantity (MOQ) for OEM and ODM production starts at 300 pieces, which gives flexibility to both boutique retailers and bulk wholesalers. Production runs are managed with technical oversight to sustain quality and surface consistency between items in larger lots.

Packaging customization extends to labeling, barcoding, and retail-ready presentation. Buyers can request specific carton dimensions, color-printed boxes, or branded inserts for enhanced shelf display. All packaging and product finishes adhere to FSC, ISO9001, and EN71 compliance standards, supporting international trade requirements and ensuring material safety for regulated markets.

Final Thoughts

Sourcing hand-carved wooden birds directly from certified factories gives retailers a dependable route to consistent quality, ethical materials, and fair pricing. By cutting out intermediaries, buyers gain control over both sustainability documentation and design flexibility while maintaining cost transparency. With materials like basswood and Java wood, each product achieves a mix of strength, lightness, and detailed craftsmanship that appeals to diverse retail markets.

As global demand continues to favor verified sustainable goods, factories equipped with in-house carving, finishing, and packaging systems stand out as key partners for long-term retail supply. Combining FSC or PEFC-certified sourcing with tailored OEM and ODM options supports business growth and environmental responsibility at the same time. Direct collaboration with manufacturers like Ewoodarts simplifies every stage—from design to delivery—making wooden bird products ready for competitive retail distribution worldwide.

Frequently Asked Questions

Is Ewoodarts a direct factory?

Yes, Ewoodarts operates as a direct manufacturer in Changchun, China. The company manages the entire production process in-house—from sourcing premium basswood and Himalayan salt to carving, finishing, and quality inspection. It has over 21 years of factory experience and supports multiple shipping and payment terms.

What is the MOQ for wholesale?

For most wooden bird wholesale orders, the minimum order quantity is 100 pieces for stock items and 300 pieces for custom OEM or ODM designs. These quantities align with industry norms, balancing production cost and efficiency for handcrafted products.

Can I mix species in one carton?

Yes, you can combine different bird species or styles within a single carton. Mixed packaging is supported since these carved pieces are made from various woods and designed to ship together without restrictions.

Do you offer DDP shipping?

Yes, DDP shipping is available. This means Ewoodarts handles all logistics—including freight, customs clearance, duties, and taxes—until the goods reach your location. You simply receive the order at your chosen destination.

Are your products FSC certified?

FSC certification for wooden products is optional and depends on the supplier’s chain-of-custody documentation. Ewoodarts can provide wood sources and certifications upon request, though not all carved bird models carry the FSC label.

What is the lead time for 1000 pcs?

The usual lead time for producing 1000 hand-carved wooden birds is around 60 days. Timeframes can vary slightly by style, complexity, and seasonal production load.