Improper Wood Moisture Content control is the leading cause of cracking in wooden decor, resulting in unsellable inventory and negative reviews. Since most warranties exclude environmental damage, the financial risk of product failure falls entirely on the importer, eroding margins with every customer return.

This document details our non-negotiable 8-12% kiln-drying standard for exports. We outline our multi-stage conditioning process for Premium Basswood and Pine, giving you the technical data needed to verify source-to-shelf integrity and protect your investment.

Wood Cracking Issues

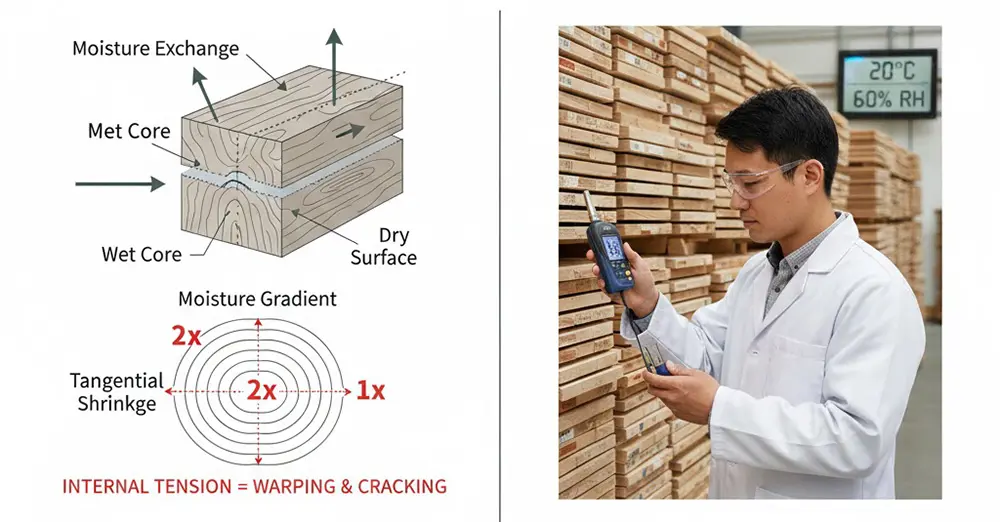

Wood cracking is caused by drying stress when different parts shrink at uneven rates. This is a natural result of moisture gradients that require careful management during the drying process.

The Science of Drying Stress and Cracks

Wood cracks happen because of internal stress created during drying. The surface of a piece of wood always loses moisture and dries faster than its interior core. This difference, known as a moisture gradient, is the root cause of the problem.

The issue is compounded by how wood shrinks. It shrinks along its growth rings (tangentially) at nearly double the rate it shrinks across them (radially). This uneven shrinkage creates powerful internal tension. Once the wood’s moisture content drops below its fiber saturation point, typically around 25-28%, that tension can become strong enough to physically pull the wood fibers apart, causing cracks.

Minimizing Risk with Premium Wood and Quality Control

Controlling cracking starts with smart material selection. We use fine-grained Basswood and resilient Mongolian Pine, specifically chosen for their stable and predictable drying characteristics. These premium softwoods respond better to controlled drying, which reduces the risk of defects from the start.

Our rigorous quality control process is built around this reality. We implement precise humidity management to ensure the wood dries as uniformly as possible. By carefully controlling the drying rate, we prevent the severe internal stresses that lead to cracking, ensuring every handcrafted product meets commercial quality standards.

Understanding EMC

Equilibrium Moisture Content (EMC) is the point where wood’s moisture level balances with the surrounding air. At EMC, wood stops gaining or losing moisture, preventing cracks and warping.

How Wood Reaches Environmental Balance

Wood is hygroscopic, meaning it constantly tries to match the moisture level of the air around it. EMC is the point where the wood’s internal moisture stabilizes with the surrounding relative humidity. If a piece of wood isn’t at EMC, it will either absorb or release moisture to find that balance. This process causes the wood to physically swell or shrink, which leads to warping, bowing, and cracking. Once a crack forms, the damage is permanent.

For this reason, achieving the correct EMC is not just a technical detail—it’s a critical step for product integrity. Any carving, painting, or finishing must happen *after* the wood is stable. Working with unstable material guarantees that the final product will eventually deform, compromising its quality and lifespan.

Our Approach to Material Stability

We apply this principle directly to our manufacturing. The process starts with selecting premium Basswood and Pinewood, ethically sourced from Changbai Mountain. These woods are chosen for their workability and consistent grain, but their real value is unlocked through proper conditioning. As a core part of our Rigorous Quality Control, we manage the wood’s humidity levels long before carving begins.

This proactive stabilization ensures the material won’t shift or crack later in its lifecycle, whether it’s on a shelf in a humid climate or a dry one. It’s a fundamental part of our ‘Source-to-Shelf Integrity’ promise, making sure every hand-carved duck we produce is built on a foundation of stable, reliable material.

Source Premium Hand-Carved Wholesale Ducks

Secondary Kiln Drying

“Secondary kiln drying” isn’t a standard term but refers to our advanced conditioning process. After initial drying, we use equalization and stress-relief cycles to maximize wood stability.

Drying wood is one thing; stabilizing it is another. Standard drying can leave internal stresses in the timber, leading to cracks, warping, and checking long after the product is finished. This is a major liability for any wholesaler or retailer. We use a multi-stage conditioning process to eliminate these risks from the start.

| Stage | Objective | Method |

|---|---|---|

| 1. Initial Drying | Reduce overall moisture content below the fiber saturation point. | Controlled heat and air circulation to remove the bulk of the water. |

| 2. Equalization | Achieve uniform moisture content from the core to the surface. | Adjusting humidity to allow wetter core sections to catch up with drier surfaces. |

| 3. Conditioning | Relieve internal stresses built up during shrinkage. | Briefly introduce high-humidity, high-temperature steam to relax wood fibers. |

Defining Multi-Stage Wood Conditioning

This process goes far beyond simple drying. It’s a carefully controlled, multi-phase procedure designed to create exceptionally stable wood. After the initial drying phase removes most of the moisture, the wood enters distinct equalization and conditioning stages.

The main goal is to get every fiber in a piece of wood to a uniform Equilibrium Moisture Content (EMC). This prevents the core from being wetter than the surface, which is a primary cause of future warping. To finish, we use high-humidity relief treatments to relax the internal tension created during shrinkage. This final step is what prevents the wood from cracking or moving later.

Our Quality Control for Optimal Wood Stability

We apply this rigorous conditioning process to manage humidity levels in every batch of our Premium Basswood and Mongolian Pinewood. It’s a critical quality control step that ensures our ‘Source-to-Shelf Integrity’ by stopping moisture-related defects before they ever happen.

For hand-carved products, stability is non-negotiable. Properly conditioned wood is the foundation of the ‘Master Craftsmanship’ our partners expect. It guarantees that the intricate, hand-carved details will remain intact, whether the final product is sitting in a warehouse or a customer’s home.

Air Dried vs. Kiln Dried

Kiln drying is a fast, controlled process ensuring low, consistent moisture content and pest elimination. Air drying is slow and variable, making kiln drying superior for manufacturing stability.

Core Differences: Process, Speed, and Stability

Kiln drying is an industrial process. We use controlled heat and humidity to bring wood down to a precise 6-8% moisture content in about 6-8 weeks. This systematic approach eliminates guesswork and creates a predictable raw material. Air drying is the opposite; it’s a passive method that relies on local climate and can easily take over a year to complete.

The final moisture level of air-dried wood is entirely dependent on the surrounding environment, making it inconsistent. A batch dried during a humid season will behave differently than one dried in a dry season. Kiln drying’s controlled environment produces a stable and uniform material, which is non-negotiable for commercial production where every product must meet the same standard.

A major advantage of the kiln is sterilization. The high heat effectively kills any pests, mold spores, or bacteria within the lumber. Air drying offers no such guarantee, introducing a risk of contamination or infestation that can compromise an entire shipment of finished goods.

Ensuring Consistency Through Precise Humidity Control

For anyone buying in bulk, the variability of air-dried wood is a serious liability. It introduces an unacceptable risk of defects, warping, and cracking that can appear long after the product is finished. This inconsistency makes it impossible to guarantee the quality of a large order.

Our quality control process is built around managing moisture from start to finish. Precise humidity management is critical because drying-related defects like cracks are permanent. You can’t fix them later. By controlling the drying process, we prevent these internal stresses from ever forming, ensuring the structural integrity of the wood.

This rigorous, controlled approach is how we deliver on our promise of ‘Bulk-ready Precision.’ It means every hand-carved duck you receive is carved from stable, properly seasoned wood. This ensures each piece meets strict export quality standards and will remain intact, whether it’s on a shelf in California or a store in Germany.

Testing Methods

Wood moisture is measured two ways. The oven-drying method is the precise lab standard but is destructive. For daily quality control, electronic meters provide fast, non-destructive assessments.

Core Approaches to Moisture Measurement

In manufacturing, you can’t manage what you don’t measure. For wood moisture, the industry relies on two primary techniques. One is the definitive, destructive lab standard, and the other is the practical, everyday tool for the factory floor.

- Oven-Drying Method (ASTM D4442): This is the gold standard for accuracy. It involves weighing a wood sample, drying it in an oven until its weight is constant, and calculating the moisture content. It’s used for calibrating other equipment and for lab analysis, not for production line checks.

- Electronic Moisture Meters: These are the workhorses for quality control. The portable devices give instant readings in the field or factory. They come in two main types: pin-type meters that measure electrical resistance and non-destructive pinless meters that use electromagnetic waves.

Ensuring Quality with In-Process Testing

For our handcrafted wooden ducks, theoretical standards aren’t enough. We embed testing directly into our process. Electronic meters are critical to our multi-stage quality control, giving us the ability to perform rapid checks on raw lumber and again on semi-finished products before final painting and assembly.

This rigorous testing ensures every piece of Basswood or Mongolian Pinewood meets the precise humidity levels required for stability. It’s a non-negotiable step that underpins our commitment to source-to-shelf integrity, preventing cracks and warping long before the product ever reaches your warehouse.

Climate Advice

Wooden ducks can expand or contract based on local humidity. We use properly dried Premium Basswood and Resilient Pine to ensure stability in diverse climates, from Europe to the USA.

How Regional Humidity Impacts Wooden Crafts

Wood is a natural material that constantly tries to match the moisture level of the air around it. It absorbs or releases moisture to find a balance, a state known as Equilibrium Moisture Content (EMC). This isn’t a defect; it’s just how wood behaves.

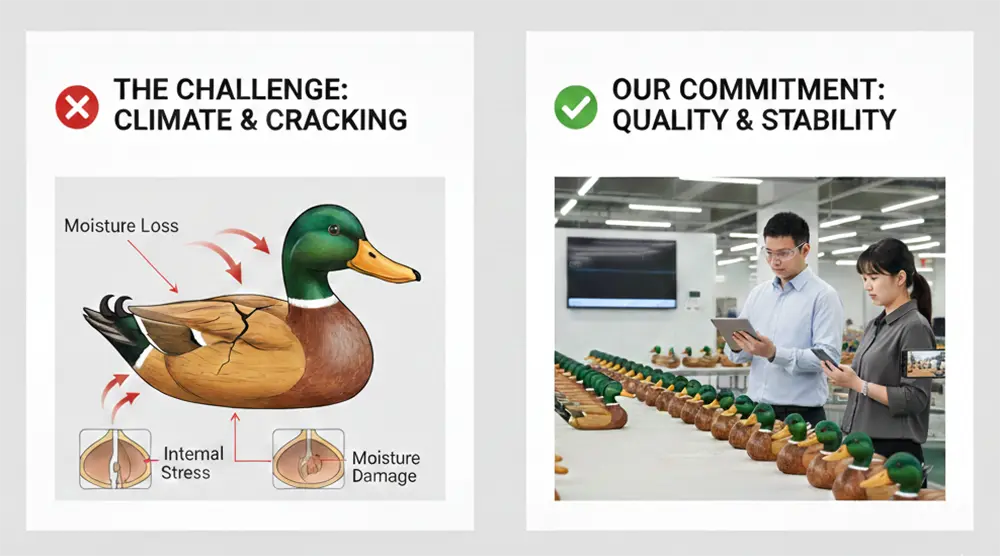

When a wooden product is shipped to a location with high humidity, it can absorb moisture and swell slightly. In a dry environment, like a heated home in winter, it will release moisture, which can cause it to shrink. If this change happens too quickly, the internal stress can lead to fine cracks or checking.

Material Selection for Global Climate Resilience

We anticipate these environmental shifts. That’s why we exclusively use Premium Basswood and Mongolian Pinewood. We select these species for their inherent stability and fine, consistent grain, which makes them less prone to dramatic swelling or shrinking.

Our timber comes from the managed forests of Changbai Mountain. We properly season and dry it to a specific moisture content that performs reliably across our key export markets in Europe and the United States. This careful material preparation minimizes climate-related issues for our international clients and their customers.

Warranty

Most warranties for wood products don’t cover damage from environmental moisture. Our guarantee is our process—rigorous quality control from wood sourcing to pre-shipment verification.

Standard Exclusions for Wood Products

Wood is a natural material that breathes; it expands and contracts based on ambient temperature and humidity. Because we can’t control the product’s final environment, no manufacturer can warranty against issues caused by climate. These are standard industry exclusions.

- Moisture Damage: Wood cracking is primarily caused by drying stress when the material loses moisture to a dry environment. This is a natural reaction, not a manufacturing defect. Any damage from excessive humidity, water, or extreme climate fluctuations after delivery is not covered.

- Natural Material Changes: Minor cracking or checking can occur if the product is kept outside of a stable, climate-controlled setting. This is an inherent characteristic of wood.

- End-User Handling: We can’t be responsible for issues that arise from improper handling, assembly, or storage after the product has been received.

Our Commitment to Quality and Craftsmanship

Our guarantee isn’t a piece of paper, it’s built into our production line. We stand behind our work by ensuring every piece meets our standards before it ever leaves the factory, protecting your investment and your business.

- Rigorous Quality Control: We implement a multi-stage QC process that verifies product integrity at every step, from the initial carving to the final coat of paint.

- Pre-Payment Verification: We protect your cash flow. You receive high-resolution photos and videos of your completed order for approval before you pay the final 70% balance. What you see is exactly what you get.

- Artisanal Variance: We embrace the unique character of 100% hand-carved products. Slight variations in grain, color, or posture aren’t defects—they are the signature of authentic craftsmanship, ensuring no two ducks are identical.

Final Thoughts

Sourcing cheaper, improperly dried wood directly exposes your business to customer complaints and returns from cracking. Our multi-stage kiln drying and Rigorous Quality Control are your defense against these margin-killing defects. This process is how we deliver Source-to-Shelf Integrity.

Don’t just read about our standards—prove them for yourself. We recommend a trial order to see the Master Craftsmanship and material stability firsthand. Contact us to get your sample shipment started or to discuss your OEM requirements.

While looking for specific styles, don’t forget to check our full catalog of [Wholesale Wooden Ducks] to see all available options.