Businesses looking to bring custom wood designs to market face the challenge of balancing artisanal aesthetics with rigorous manufacturing standards. We bridge this gap by integrating 22 years of experience to ensure every piece meets global safety requirements and material standards.

We outline our complete concept-to-production workflow.You will find specific details on prototyping costs ranging from $30 to $250,000, along with the technical differences between shop and fabrication drawings used to guide our 300-piece minimum production runs.

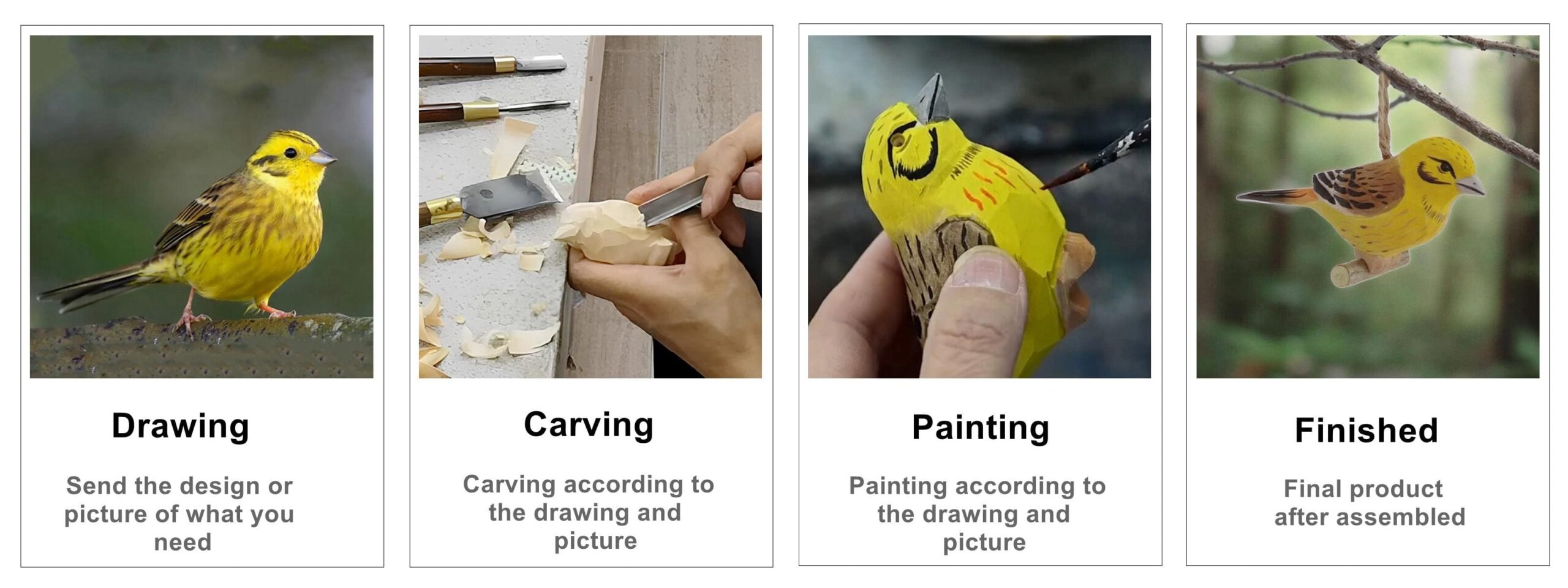

Your Design, Our Craftsmanship

We transform client concepts into market-ready products by integrating 22 years of artisanal experience with technical validation. Our process converts initial sketches into detailed CAD models, ensuring custom designs align with global safety and material standards.

Technical Concept-to-Production Conversion

We translate artwork and digital files into formal CAD specifications with explicit tolerance definitions. Our engineering team applies Design for Manufacturing (DFM) principles to optimize product geometry and reduce production costs. We select sustainable basswood and Himalayan salt based on ASTM material specifications to ensure long-term durability. Our engineers provide proactive design feedback to identify manufacturability constraints before mass production begins.

Quality Compliance Standards

Our facility implements Geometric Dimensioning and Tolerancing (GD&T) to ensure consistent quality across 300-piece minimum orders. We maintain ISO 9001, FSC, and BSCI certifications to provide full traceability and ethical manufacturing oversight in 2026. We conduct multi-stage inspections to meet EN71-1/-2/-3 safety requirements and UKCA standards for international retail.

The OEM Process (Step-by-Step)

By 2026, our OEM process uses a 7-stage gated methodology to turn concepts into market-ready products. We manage everything from design review and DFM closure to Golden Sample approval, followed by mass production under strict AQL sampling standards to guarantee consistent excellence.

| Manufacturing Phase | Critical Deliverable | Quality Objective |

|---|---|---|

| Design Validation | DFM Analysis & BOM | Resolve technical risks before tooling investment. |

| Prototyping | Labeled Golden Sample | Lock the “single source of truth” for production. |

| Execution & QC | AQL & FQA Reports | Confirm compliance with ISO 9001 and FSC standards. |

Design Validation and Sample Approval

We perform a Design for Manufacturability (DFM) analysis to resolve technical issues before starting the tooling phase. This evaluation identifies potential assembly bottlenecks or material stresses early, so we avoid costly rework and schedule slips during mass production.

Our team delivers Phase 1 requirements, including detailed technical drawings and a complete Bill of Materials (BOM), within the first two weeks. These documents establish the engineering foundation and ensure every measurement aligns with the initial project specifications.

We establish a labeled Golden Sample that serves as the single source of truth for all production measurements and aesthetic standards. By locking this sample before issuing a Purchase Order, we provide a physical benchmark that reduces the risk of downstream change orders or quality deviations.

Production Logistics and Quality Assurance

We verify material compliance through Approved Vendor Lists (AVL) and maintain traceability for all sustainable basswood and salt batches. This system tracks compliance certificates and material origins to meet buyer expectations for sustainability and safety.

Our team validates a pilot build against the Golden Sample to confirm assembly readiness, torque settings, and fixture accuracy. Testing the production line at a small scale confirms that the facility can replicate the approved quality levels consistently under full-speed conditions.

We apply AQL sampling plans and Final Quality Assurance (FQA) checklists to meet ISO 9001, FSC, and BSCI requirements before shipping. These inspections use labeled photos and documented pass/fail criteria to ensure every shipment adheres to international manufacturing standards.

Providing Drawings vs. Samples

Digital drawings offer precise, scalable instructions that follow ISO and ANSI standards to ensure production accuracy. While physical samples provide a tangible reference for fit and finish, CAD-based drawings allow for rapid edits, detailed tolerances, and clear material specifications that minimize rework during the fabrication phase.

| Drawing Type | Primary Focus | Key Technical Data |

|---|---|---|

| Shop Drawings | Construction Integration | Dimensions, material connections, and site tolerances. |

| Fabrication Drawings | Part Production | Welding symbols, bend deductions, and hole sizes. |

| Engineering Drawings | System Functionality | Mechanical placement and electrical component routing. |

| Assembly Drawings | Final Configuration | Bill of Materials (BOM) and exploded part views. |

Technical Differences Between Shop and Fabrication Drawings

Shop drawings define the dimensions and material connections necessary for construction integration. These documents allow engineers to verify how components fit within a larger project framework. Fabrication drawings specify precise measurements for welding, bending, and bolt locations. Workshop teams rely on these details to execute production tasks without ambiguity.

Engineering drawings outline the functional placement of mechanical and electrical components. These plans ensure that every unit operates correctly within the intended system. Assembly drawings use ballooned views and a Bill of Materials (BOM) to show how individual parts fit together. This documentation provides a clear roadmap for the final assembly stage without requiring individual part creation specs.

Industry Standards and File Format Requirements

Production teams use ISO, ANSI, and AWS standards to maintain consistent quality across different manufacturing units. Adhering to these global benchmarks ensures that parts meet safety and performance requirements. CAD-based formats like DXF and BIM files enable high-precision CNC machining and clash detection. These digital assets help identify potential interference issues before physical fabrication starts.

Manufacturing specifications include surface finish requirements and hardware lists to ensure the final product matches the design intent. Detailed notes on coatings and finishes prevent corrosion and ensure aesthetic consistency. Digital blueprints act as the primary legal and manufacturing reference. These drawings outrank physical samples in cases of tolerance disputes because they provide verifiable, objective measurements for quality control.

Transform Your Vision into Market-Ready Custom Products

Prototyping Costs & Timelines

Prototyping costs range from $30 for basic 3D prints to over $250,000 for complex engineering assemblies. Development schedules typically run between one week for initial mockups and 12 weeks for integrated electronics and firmware testing.

Cost Breakdown by Material and Method

Financial requirements for prototypes depend heavily on material selection and production methods. Entry-level 3D printed models start at $30 for basic shapes, while complex assemblies featuring integrated electronics can reach $20,000. For projects requiring CNC machining, the specific alloy chosen impacts the budget; Aluminum 6061 prices at $25 per sheet, whereas Stainless Steel 304 costs approximately $90. Custom electronics and PCB development represent a significant investment, often between $10,000 and $50,000 per iteration. Urethane casting offers a solution for small production runs with mold costs ranging from $250 to $1,500 and individual parts priced between $20 and $50. Most mechanical prototypes require a budget between $3,000 and $30,000 based on the number of components and required tolerances.

Project Schedules and Delivery Phases

The production timeline scales with the technical complexity of the design. Engineering teams complete preliminary mockups and initial sketches within one week. Fabricating and assembling mechanical or CNC-machined prototypes takes four to eight weeks. If the project requires custom firmware and electronics integration, the schedule typically extends to 12 weeks. Engineering prototypes used for pre-production validation require a window of two to six weeks. Iterative testing cycles designed to identify thermal or structural failures add one to two weeks to the total schedule for each necessary round of adjustments.

Private Label & Branding

Private labeling enables brands to launch products in 4 to 8 weeks with minimum orders between 500 and 1,000 units. This approach utilizes pre-vetted formulas with 99.5% ingredient purity, meeting FDA and REACH standards while keeping initial costs between $5,000 and $20,000.

Operational Timelines and Financial Requirements

Private label projects require a startup investment of $5,000 to $20,000, making them more accessible than custom OEM routes. This investment range typically covers production volumes between 500 and 5,000 units, providing a manageable entry point for brands to establish their market presence without the heavy R&D costs associated with custom formulations.

Manufacturers deliver finished goods within 4 to 8 weeks by using established production templates. This speed-to-market advantage allows companies to capitalize on current trends and restock inventory much faster than bespoke manufacturing, which often requires 12 to 24 weeks for formulation and testing.

Lower MOQs starting at 500 units allow businesses to test new markets with minimal inventory risk. By leveraging manufacturer design control, brands can scale up to 5,000 units per run as demand grows, maintaining flexibility in their supply chain management.

Technical Specifications and Regulatory Compliance

Formulas maintain a specific pH range of 4 to 7 to ensure product stability and effectiveness. For products like shampoos, these benchmarks serve as performance testing standards that guarantee the product remains safe and functional throughout its shelf life.

Ingredients exceed 99.5% purity levels and keep restricted substances below 0.1% to meet GHS and REACH protocols. High-purity chemicals, including allantoin and glycerin, are screened to ensure total impurities stay below 0.01%, meeting the strict safety requirements of international regulatory bodies.

Production facilities provide essential documentation including SDS, COAs, and GMP certificates for all branded orders. These documents prove the manufacturer follows Good Manufacturing Practices and that every batch complies with FDA standards and global safety certifications.

Intellectual Property Protection

We protect intellectual property through a multi-layered system including non-disclosure agreements and technology transfer agreements. These legal frameworks define ownership of original designs and derivative works. Operational safeguards like supply chain segmentation and secure digital transfers prevent unauthorized access to proprietary manufacturing data.

Confidentiality Frameworks and Ownership Agreements

Protecting proprietary designs starts before the manufacturing process begins. We execute non-disclosure agreements (NDAs) during the initial Request for Quotation (RFQ) stage to secure sketches and material specifications. Technology Transfer Agreements (TTAs) define the ownership of improvements and derivative manufacturing innovations discovered during production. These legal obligations extend to sub-contractors and tier-2 suppliers to maintain integrity across the entire supply chain. Contract terms also include non-compete durations that prohibit manufacturers from developing competing products during or after the partnership.

Operational Safeguards and Information Control

Technical and physical methods prevent data leakage throughout the production cycle. Supply chain segmentation ensures that external vendors only receive data for generic components, while specialized parts remain restricted. We protect CAD drawings and technical specifications using secure file transfer protocols and data encryption. Regular IP audits identify and safeguard proprietary technologies, such as specific wood-drying techniques or processing methods. Maintaining ISO 9001 standards provides a framework to document quality control while keeping specific manufacturing trade secrets confidential.

Final Thoughts

Choosing a manufacturing partner involves more than finding a factory; it requires a team that turns creative ideas into scalable products while maintaining strict quality control. We combine two decades of artisanal experience with modern engineering to help brands build their inventory.

Reliable production helps you grow your business without the constant worry of quality shifts or design theft. Using clear CAD specifications and multi-layered IP protections keeps your brand’s unique identity secure during the entire fabrication process. Since our facility follows ISO and FSC certifications, you receive products that meet global retail expectations and environmental standards. This system provides the stability needed to launch new collections and expand your market reach.

Frequently Asked Questions

Can you provide OEM and ODM services for my brand?

We offer full OEM and ODM capabilities. OEM production follows your specific schematics, CAD files, and material requirements. ODM services manage the entire cycle from initial engineering and prototyping to final manufacturing. Our facilities maintain compliance with ISO 9001:2015 and IATF 16949:2016 standards.

Is it possible to develop a product from my own drawings?

We develop custom products using your CAD files, DWG drawings, or 3D models. To ensure manufacturing accuracy, your drawings should include title blocks with part names, material specifications, and tolerances according to ISO or ASME standards.

How much do you charge for molds and samples?

Mold costs depend on production volume and design complexity. For low-volume samples start at $100. High-volume production which typically range from $5,000 to over $100,000.

Do you support private label branding?

Yes. We manufacture products to meet specific branding and packaging requirements for retailers. Private label projects generally require a minimum order of 500 units and involve lead times of 4 to 8 weeks.

How do you ensure my design remains confidential?

We sign Non-Disclosure Agreements (NDAs) to provide a legally binding framework for your intellectual property. This contract protects your drawings, prototypes, and specifications by restricting access to a need-to-know basis and establishing clear legal remedies for any unauthorized disclosure.

What is the minimum order quantity (MOQ) for custom shapes?

Our standard MOQ for custom handcrafted items starts at 300 pieces. For high-volume industrial production or specialized components, the requirement may range from 5,000 to 25,000 units depending on the specific manufacturing process and materials.