Safe Packaging (Drop Test)(Logistics) is not a line item, it’s a direct defense against costly freight claims and unsellable inventory. Relying on standard cartons for hand-carved products with fragile beaks is a direct risk to your margins, turning potential profit into write-offs upon arrival.

Our system eliminates this risk. We use a multi-layer structure combining 3-ply inner cartons with a reinforced 5-ply master carton. The entire assembly is engineered to pass the ISTA 3A Drop Test, ensuring your handcrafted carvings arrive intact and ready for sale.

Shipping Fragile Carvings

We use a multi-layer system to protect fragile carvings. Each piece gets wrapped in silk paper, secured in a 3-ply inner box, and packed into a 5-ply master carton.

Best Practices for Transit Safety

Protecting delicate, handcrafted items during shipping isn’t about luck, it’s about a systematic approach. The goal is to isolate and cushion each piece to neutralize the shocks and vibrations common in international freight. Without proper separation and reinforcement, even the most robust products risk damage.

- Individual Wrapping: Every carving is wrapped separately. This prevents items from scratching or hitting each other directly.

- Inner Box Immobilization: We use inner boxes to stop the items from shifting. Any movement inside the carton during transit is a potential source of breakage.

- Shock Absorption: A strong outer carton acts as the primary shield. It’s designed to take the brunt of impacts from rough handling, drops, and compression.

Our Protective Packaging Specifications

Our packaging isn’t just a box, it’s an engineered system built to ensure your order arrives intact. We use specific materials that have been tested to withstand the rigors of global shipping, whether by air or sea.

- Primary Layer: Each carving is carefully wrapped in protective silk paper to guard against surface scuffs and minor impacts.

- Inner Carton: Products are then secured inside 3-Ply BC Flute inner cartons. This step isolates products and adds a crucial layer of structural integrity.

- Master Carton: The inner boxes are packed into a 5-Ply reinforced corrugated master carton. This outer shell is built to pass the ISTA 3A Drop Test, a standard that simulates the real-world hazards of parcel delivery systems.

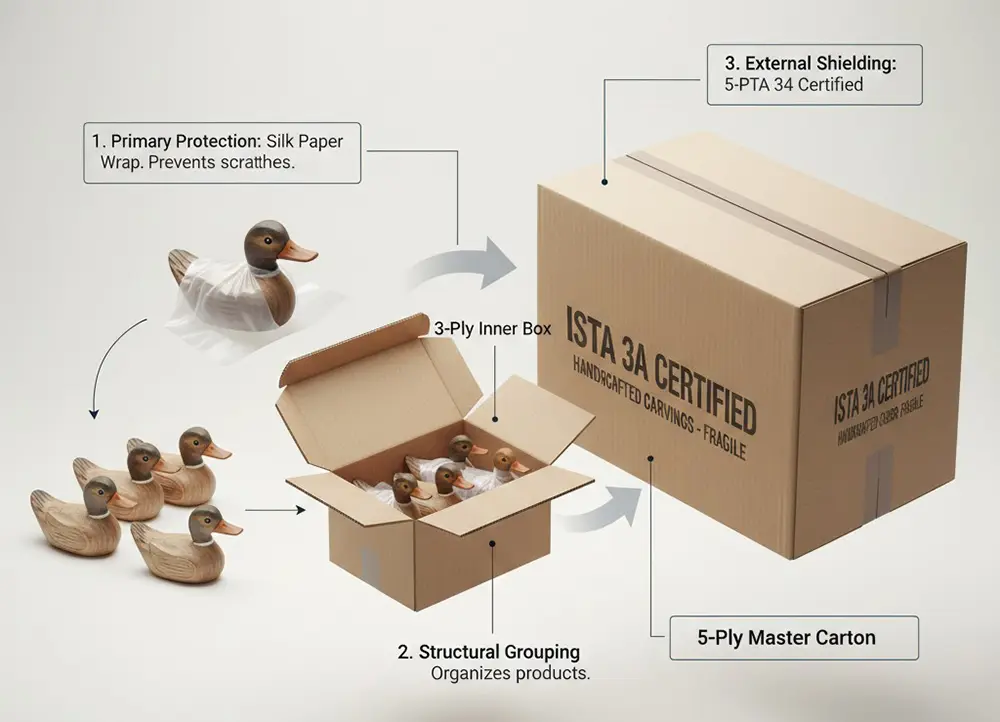

Packaging Anatomy

Our multi-layer system uses silk paper, a 3-ply inner box, and a 5-ply master carton. This structure is engineered to pass the ISTA 3A Drop Test for global transit.

Core Components of a Protective System

Any effective packaging for fragile goods relies on a simple, layered defense. Each component has a specific job to absorb shock and prevent damage from the factory to the warehouse floor.

- Primary Protection: The first layer, like silk paper, directly shields the item’s surface from scratches and minor cosmetic scuffs.

- Structural Grouping: Inner boxes organize products into stable blocks. This stops individual items from colliding with each other inside the main carton during rough handling.

- External Shielding: A tough outer carton serves as the primary barrier. It takes the brunt of impacts, compression from stacking, and other stresses during transit.

Our Multi-Layered Carton Specifications

We don’t leave product safety to chance. Our packaging system is built with specific, field-tested materials designed to protect hand-carved products during complex international shipping routes.

- Individual Silk Paper Wrap: Every hand-carved duck gets a dedicated wrap. This preserves the hand-painted finish and prevents abrasion between units.

- 3-Ply Inner Box: We group the wrapped items into a sturdy 3-Ply BC Flute carton. This adds a critical layer of rigidity and keeps products organized.

- 5-Ply Master Carton: The final shipment is packed into a reinforced 5-Ply BC Flute export carton. We engineered this carton to pass the ISTA 3A Drop Test, ensuring it withstands the demands of both air and sea freight.

Source Premium Hand-Carved Ducks Direct

Drop Test Standard

Drop test standards like ISTA 3A simulate shipping impacts. Our reinforced, 5-ply master cartons are engineered to pass these tests, ensuring your handcrafted products arrive safely.

| Standard Drop Test Principles | How Our Packaging Complies |

|---|---|

| Protocols assess packaging durability against free-fall impacts and handling shocks common in global shipping. | We use reinforced 5-Ply BC Flute corrugated board for all master cartons, a material selected for its strength and resilience. |

| Testing involves dropping packages from specific heights onto their faces, edges, and corners to find structural weaknesses. | Our packaging is engineered to pass the rigorous ISTA 3A Drop Test, a comprehensive simulation for parcel delivery systems. |

| International standards from ISTA and ASTM set the benchmark for quality and product safety during transit. | This certification minimizes damage risk, providing reliable protection for your fragile, handcrafted carvings from our factory to your warehouse. |

Simulating Real-World Shipping Impacts

Drop tests aren’t random. They are standardized protocols that assess how well packaging protects its contents against the bumps, drops, and shocks that happen during global shipping. The goal is to replicate real-world conditions in a controlled lab environment to ensure packaging is fit for purpose.

The methodology is straightforward. A packaged product is dropped from specific heights onto its most vulnerable points—its faces, edges, and corners. This process systematically identifies potential structural weak points before a product ever leaves the factory. Key international bodies like the International Safe Transit Association (ISTA) and ASTM set the global benchmarks for these tests, defining what good packaging actually looks like.

Our ISTA 3A Certified Master Cartons

We don’t leave product safety to chance. We use a reinforced 5-Ply BC Flute corrugated board for all master cartons. This material is not a generic choice; we selected it specifically for its superior strength and impact resilience, which is critical for protecting handcrafted goods.

Our packaging is engineered and validated to pass the ISTA 3A Drop Test. This is a tough, comprehensive simulation designed for individually packaged products shipped through parcel delivery systems. Passing this test confirms that our cartons provide reliable protection for your fragile, handcrafted wooden carvings. This level of quality control ensures your inventory arrives intact and ready for sale, protecting your investment from our factory door to your warehouse floor.

Master Carton Specs

Our master cartons use reinforced 5-ply BC flute corrugated board and are sized at 58x44x31cm. This build passes the ISTA 3A Drop Test for robust protection during air and sea freight.

Protecting handcrafted goods across thousands of miles of ocean or air transit isn’t a guessing game. It requires packaging engineered specifically for the job. The master carton is the primary line of defense for your wholesale order, and its material and construction directly impact whether your products arrive in sellable condition.

Material Strength and Structure

Corrugated cardboard is the industry standard for a reason: its layered structure provides exceptional rigidity against crushing and punctures. The strength comes from the number of layers (ply) and the internal corrugated medium (the flute). A multi-ply board is essential for absorbing the shocks common in global logistics.

Inside the master carton, individual inner boxes add another layer of protection. This box-within-a-box system, combined with dividers, prevents items from shifting and colliding during transit. It’s a simple, effective way to ensure the structural integrity of the entire shipment.

Our 5-Ply Export-Grade Solution

We don’t leave packaging to chance. Our cartons are built to a specific, tested standard to guarantee the safe arrival of our wooden ducks. Here are the exact specifications:

- Master Carton Material: We use a 5-Ply BC Flute Export Carton. This reinforced board is designed for the rigors of stacking and handling in shipping containers.

- Inner Box Material: Each inner box uses 3-Ply BC Flute corrugated board, providing a critical secondary layer of protection for the products inside.

- Durability Standard: Our entire packaging system is engineered to pass the ISTA 3A Drop Test, a protocol that simulates common shipping conditions for individual parcels.

Container Loading

Proper container loading maximizes space and balances weight to stop cargo shifts. Our standardized 5-ply master cartons ensure a secure, predictable stack, protecting our hand-carved wooden products.

Maximizing Space and Cargo Stability

The main goal of container loading is to use every cubic inch of available space. Filling a container efficiently lowers the per-unit shipping cost, which directly impacts your profit margins. Wasted space is wasted money.

A solid loading plan creates a tight, interlocking stack of cartons. This “bracing” technique prevents cargo from shifting, sliding, or tumbling during rough sea transit. Any movement inside the container can lead to damaged goods and financial loss.

Evenly distributing the total weight across the container floor is also critical. A balanced load prevents instability during lifting and transport at ports. It ensures the container can be handled safely by cranes and trucks without risk.

Standardized Cartons for Efficient Stacking

We don’t leave packing to chance. Every shipment uses our reinforced 5-Ply BC Flute Export Cartons. This material is specifically chosen to withstand the immense compression forces and humidity changes common in international sea freight.

Our master cartons have uniform dimensions, typically 58cm x 44cm x 31cm. This consistency allows our loading teams to build predictable and stable stacking patterns. There’s no guesswork, just a secure, solid wall of cartons that supports itself.

We also manage the gross weight of each carton to stay between 8.0kg and 15.0kg. This range is optimal for safe manual handling by warehouse staff and helps achieve a perfectly balanced load distribution inside the container.

Broken Goods Policy

We prioritize prevention over claims. Our reinforced, 5-ply master cartons and ISTA 3A certified packaging are engineered to ensure your handcrafted wooden ducks arrive intact.

Damage Classification and Claims

In any logistics operation, damage can occur. It’s typically classified in two ways: visible damage, like a crushed or punctured box noticed upon delivery, and concealed damage, which is only found after unboxing. We follow standard industry procedures for both.

Responsibility is shared. Our job is to ensure every shipment is packed to withstand normal transit hazards. The logistics company’s job is to handle the packages safely from our facility to your warehouse. A successful freight claim requires documentation showing the goods were in perfect condition when they left our factory and were damaged upon arrival.

Prevention with Reinforced Packaging

Our entire policy is built around making claims unnecessary. We invest in packaging that eliminates breakage from the start, protecting your inventory and profit margins. Here’s how we do it:

- Individual Protection: Each hand-carved duck is wrapped in protective silk paper before being placed into a sturdy, 3-ply inner box.

- Master Carton Strength: We use 5-Ply BC Flute Export Master Cartons. This is a reinforced corrugated board designed specifically for the stresses of international air and sea freight.

- Certified Durability: Our complete packaging system passes the ISTA 3A Drop Test, an industry standard that certifies its ability to withstand the drops, vibrations, and impacts common in parcel delivery systems.

This focus on rigorous packaging means you can order with confidence, knowing the risk of damaged goods has been systematically engineered out of the process.

Labeling/Barcoding

Accurate labeling is critical for a smooth supply chain, ensuring every carton is tracked from our factory to your warehouse. We provide complimentary barcode stickers, inner box labels, and shipping marks for all wholesale orders.

The Role of Barcodes in Supply Chain Visibility

In global trade, every carton needs a clear identity. Barcodes and proper labels provide that identity, acting as a digital passport for your shipment. This system eliminates guesswork and manual entry, which is crucial for moving goods efficiently across borders and into your inventory.

- It ensures real-time traceability as shipments move through different carriers and checkpoints.

- It gives retailers and wholesalers an accurate tool for managing stock levels and receiving goods.

- It significantly reduces handling errors and speeds up processing at customs and fulfillment centers.

Complimentary Labeling Service for B2B Partners

To streamline the receiving process for our wholesale partners, we manage all essential labeling directly at our factory. This is a complimentary service included with every order, ensuring your products arrive ready for your warehouse systems without any extra work on your end.

- We apply barcode stickers for each individual item or on the inner boxes, depending on your requirements.

- Custom inner box labels are used for clear product identification and quantity counts.

- All master cartons feature standardized shipping marks for correct freight handling and routing.

Frequently Asked Questions

How many wooden ducks fit in one master carton?

The number of ducks per carton varies by size to ensure safe transit. A standard master carton holds approximately 720 of our 6cm mini ducks, 240-300 of the 10-12cm ducks, or 24-96 of the larger 20cm ducks.

Can I get custom boxes with my own branding?

Yes, we provide custom packaging solutions for brand owners and retailers, including branded color boxes and specialized gift packaging. The minimum order quantity for custom-printed boxes is 500 units.

What happens if some items arrive broken?

We use a robust, multi-layer system to prevent damage. Each carving is wrapped in silk paper and secured in 3-ply inner boxes within a 5-ply master carton designed to pass the ISTA 3A Drop Test. Damage is rare, but we have a clear policy to address any issues that may occur.

Do you offer plastic-free packaging?

Our standard packaging is designed to be as eco-friendly as possible. We use protective silk paper and recyclable, corrugated cardboard for both inner and master cartons, significantly minimizing the use of plastics.

While looking for specific styles, don’t forget to check our full catalog of [Wholesale Wooden Ducks] to see all available options.