Launching a nature-themed retail brand requires a balance between curated aesthetics and limited startup capital. New shop owners often struggle to source high-quality, sustainable inventory without committing to massive production runs that drain their budget.

We examine how to build an inventory of basswood carvings and mineral products using 300-piece Minimum Order Quantities (MOQs) to manage financial risk. This guide breaks down the logistics of mixing SKUs to meet supplier thresholds, selecting cost-effective freight options, and utilizing private label frameworks to reduce market entry costs by 75% compared to custom development.

Curating a Niche Nature Shop

Success in niche nature retail for 2026 requires balancing sustainable raw materials with verified certifications. Startups focus on small-batch collections of handcrafted wood and authentic mineral products to minimize risk while maintaining high aesthetic and ecological standards.

Selecting Sustainable and Handcrafted Product Lines

Retailers use 300-piece Minimum Order Quantities (MOQs) to manage inventory risk while enabling seasonal variety. This approach supports the rotation of artisan designs, including hand-carved birds and wooden ornaments, to keep the storefront catalog fresh for recurring customers without requiring massive warehouse overhead.

Combining sustainable basswood carvings with authentic Himalayan salt crystals establishes a premium brand identity rooted in natural textures. Product selection must align with the 2026 demand for functional decor. Items like wooden pens and salt therapy lamps represent effective entry points into the niche market, blending ecological appeal with daily utility to meet modern gift-giving trends.

Material Standards and Quality Verification

Sourcing protocols must prioritize ethical transparency. Suppliers providing Forest Stewardship Council (FSC) certification and Business Social Compliance Initiative (BSCI) reports offer the necessary assurance of sustainable harvesting and fair labor practices, which are essential for brand credibility.

Environmental stability is critical for natural wood inventory. Implementing strict humidity control throughout the supply chain prevents warping or splitting, maintaining the structural integrity of hand-carved goods as they transition through different climate zones.

Authenticity verification for minerals involves inspecting Certificates of Origin. For Himalayan salt products, these documents confirm the material comes from designated mining regions, ensuring the mineral composition and purity meet consumer expectations for therapeutic and wellness applications.

Understanding MOQ & MOA

Minimum Order Quantity (MOQ) and Minimum Order Amount (MOA) function as financial safeguards for manufacturers. These thresholds ensure that production runs cover fixed costs like machine setup, labor, and raw material sourcing. For 2026, manufacturers like Jilin Ever Creation maintain a 300-piece MOQ to balance startup accessibility with industrial efficiency.

Core Functions of MOQ and MOA

The Minimum Order Quantity (MOQ) represents the smallest volume a factory produces in a single run. Without this threshold, the labor and machine time required to prepare a production line would exceed the revenue generated by the order. Manufacturers also utilize the Minimum Order Amount (MOA) as a financial floor, often setting a target like $10,000 to cover the administrative and logistical overhead associated with processing and shipping industrial goods.

Since the time spent calibrating equipment remains constant regardless of the order size, small batches lead to inefficient use of factory floor capacity. For customized orders, factories frequently apply minimums per variant, such as requiring at least 100-300 units for each specific color or size within a larger total order.

Production Economics and Technical Thresholds

Jilin Ever Creation maintains a 300-piece MOQ for custom OEM and ODM products to balance the needs of growing brands with industrial quality standards. Larger production batches allow for better unit economics because the factory negotiates lower prices for bulk raw materials and achieves higher machine efficiency during longer runs. As order volume increases, the fixed cost per unit drops, providing a clear pricing advantage for the buyer.

Technical constraints often stem from sub-suppliers who provide base materials like basswood or salt crystals. These suppliers set their own minimums based on processing or harvest volumes, which then dictate the manufacturer’s final MOQ. Buyers requesting quantities below these established thresholds usually pay premium prices to compensate for the lack of economies of scale and the additional logistics required for small-batch handling.

Mixing SKUs to Meet Minimums

Retailers meet supplier thresholds by grouping multiple product variants—such as different hand-carved bird species or salt lamp sizes—under a single purchase order. This strategy satisfies total volume requirements, like 500 mixed pieces or a $5,000 minimum order amount, without overstocking any single item.

| Requirement Category | Standard Threshold | Optimization Goal |

|---|---|---|

| Production Batch | 500 pieces per SKU | Reach factory break-even point |

| Mixed Order Volume | 2,000 total pieces | Bypass per-item limits |

| Order Value (MOA) | $10,000 USD | Qualify for wholesale pricing |

| Logistics Minimum | 5 Master Cartons | Maximize cargo space utility |

Strategies for Aggregating SKU Volumes

Retailers consolidate orders across product variants that share raw materials to reach production lot minimums efficiently. For example, a shop might bundle various basswood crafts or different Himalayan salt blocks into one run. By negotiating a total order MOQ of 2,000 mixed pieces, businesses can often bypass the standard 500-unit requirement usually applied to individual SKUs. This flexibility will not force the buyer to overstock a single model.

Buyers also combine diverse items from a single supplier to hit financial thresholds, such as a $10,000 USD minimum order amount. This satisfies the supplier’s administrative cost controls and often secures tiered wholesale pricing. When selecting products, businesses look for items with similar manufacturing profiles.

Logistics and Economic Order Calculations

Procurement teams use the Economic Order Quantity (EOQ) formula, √(2DS/H), to balance stock levels. In this equation, D represents annual demand, S covers ordering costs, and H accounts for holding costs, which typically equal 20-30% of the inventory value. To avoid extra fees and shipping damage, managers round their mixed SKU quantities to fit standard case packs. For instance, using 144-unit increments ensures the order fits standard shipping dimensions and eliminates broken-carton surcharges.

Freight optimization requires mixed orders to fill at least five master cartons or a full pallet. This volume reduces per-unit freight expenses by maximizing the utility of the cargo space. Modern inventory management logic helps adjust reorder frequencies for these mixed pallets. By balancing a 75-unit wholesale minimum against real-time demand, companies maintain high stock turnover while satisfying the supplier’s need for volume. Startups often use pilot runs combined with 6-to-12-month forecasts to prove their long-term value to suppliers when negotiating these mixed terms.

Secure Your Brand with Expert OEM/ODM Manufacturing

Shipping Small Batches (Air vs. Sea)

Startups weigh speed against cost when shipping batches of 300 pieces or more. Air freight provides rapid 1-5 day delivery at $5-15/kg, while sea freight (LCL) reduces expenses to $0.5-2/kg and emits 10-20 times. The decision rests on inventory urgency and whether the total weight exceeds the 500kg.

| Freight Mode | Average Transit | Cost & Capacity Benchmarks |

|---|---|---|

| Air Freight | 5-7 Days | $5-15/kg; Max 250kg/pallet; 500kg/shipment |

| Sea Freight (LCL) | 30-55 Days | $0.5-2/kg; Up to 30 tons per container |

Strategic Selection of Freight Modes for Low-MOQ Orders

Air freight moves urgent, high-value goods and initial market tests. Startups use this mode to maintain lean inventory while validating product demand without waiting weeks for sea arrivals. Logistics managers prioritize air transit for electronics or time-sensitive components that require immediate shelf availability. This mode avoids the risks of port congestion but carries a significant price premium.

Less-than-Container-Load (LCL) sea freight allows multiple businesses to share container space for smaller volumes. This strategy works for shipments that exceed the 500kg air capacity limit but do not fill a full 20ft container. Using LCL enables cost-effective scaling for seasonal products like wooden crafts or specialized salts. Shifting to sea transport once a product stabilizes reduces the per-unit shipping cost by up to 80% compared to air.

Performance Benchmarks and Regulatory Compliance for 2026

Sea freight maintains a heavy cost advantage at $0.5-2/kg, while air freight costs remain between $5-15/kg. Transit times for 2026 include 1-5 days for air and 15-45 days for sea routes via LCL consolidation. Hybrid sea-air models provide a sustainable alternative for companies looking to balance speed and environmental impact. These hybrid routes cut carbon emissions by 45% compared to standard air transport, helping brands meet tightening corporate sustainability targets.

Updated 2026 EU CN codes mandate expanded documentation for small e-commerce shipments arriving through sea ports. Importers must ensure all paperwork matches the specific HS codes for their goods to avoid +10% port delays. Safety standards also restrict air transport for certain items. Lithium batteries over 100Wh are prohibited on passenger aircraft and limited on cargo flights, making sea freight the primary option for bulkier electronics or hazardous materials. While air pallets are limited to 250kg, sea containers handle 20-30 tons, allowing for much larger volume-based growth.

Payment Terms for Startups

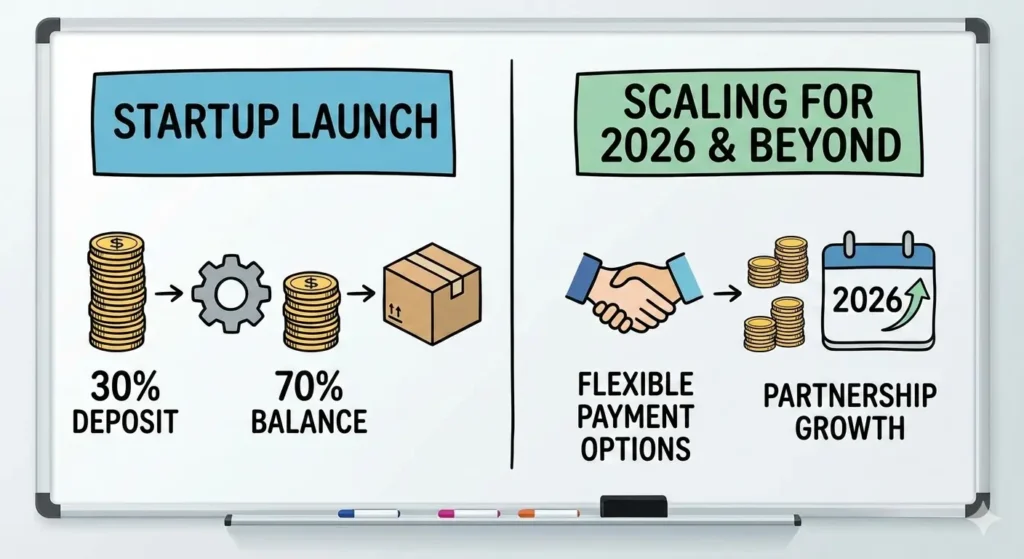

Startups typically begin with a 30% deposit to initiate production, with the remaining 70% balance due before shipment. As brands scale their order volumes toward 2026, many manufacturers offer flexible options to help manage cash flow and support long-term partnership growth.

Standard Deposit and Milestone Payments

Manufacturing agreements for emerging brands usually require an initial 30% deposit to secure production slots and purchase sustainable raw materials.The remaining 70% balance becomes due once production finishes but before the goods leave the factory floor. For custom OEM or ODM projects starting at 300 pieces, suppliers often implement milestone-based payment schedules to track progress. Brands often use third-party inspections to verify production quality before releasing the final payment, ensuring the output matches all approved technical specifications.

Net Credit and Settlement Incentives

Brands often transition to Net 30 or Net 60 terms after establishing a consistent 12-month order history with a manufacturer. These extended windows allow startups to move inventory before the full invoice amount becomes due. Many suppliers also offer 2/10 Net 30 incentives, which grant a 2% price reduction if the brand settles the invoice within 10 days. As order volumes scale toward 3,000 pieces, negotiating DDP (Delivered Duty Paid) terms helps consolidate shipping and customs costs into a single invoice. High-value shipments frequently utilize trade assurance or letters of credit to provide financial security for both the buyer and the producer during international transit.

Building a Brand with Private Label

Private labeling enables startups to launch branded products by applying custom logos and packaging to existing manufacturer designs. This strategy bypasses high R&D costs, offering 2026 market entrants a 75% cost reduction and 50% faster time-to-market compared to custom OEM development while maintaining high quality standards through verified certifications.

Strategic Framework for Private Label Market Entry

Brands build a distinct identity using a diagnostic framework that evaluates strategy, assortment pricing, marketing, and product design. This system allows businesses to transition from generic retail to ownership by focusing on high-impact visual and structural changes to proven product bases.

Selecting sustainable materials like basswood or authentic Himalayan salt meets the rising demand for eco-conscious products expected in 2026. These material choices provide a foundation for premium positioning, especially when combined with unique color schemes and custom packaging that separates the brand from generic factory-direct listings.

Aligning pricing strategies with market positioning ensures healthy margins even at lower volume tiers. By focusing on niche differentiation through branding rather than engineering, startups maintain the financial flexibility needed to scale as demand increases.

Operational Benchmarks and Technical Compliance

Capital requirements for private label projects typically range from $5,000 to $20,000. This investment level avoids the $100,000+ commitments required for custom OEM tooling and development. Production cycles of 4 to 8 weeks allow companies to maintain inventory agility and respond to seasonal trends without the long lead times associated with new product engineering.

Maintaining product integrity requires verification of ISO 9001, BSCI, and FSC certifications. These standards confirm that the manufacturing facility adheres to international safety, ethical, and environmental benchmarks. Multi-stage quality control checks ensure consistency across handcrafted goods, from the semi-finished stage to final assembly.

Minimum Order Quantities (MOQs) as low as 300 to 500 units provide a low-risk environment for testing new designs. This approach limits the capital tied up in inventory storage and enables brands to iterate on product versions based on real-time market feedback.

Final Thoughts

Retailers build resilient brands by starting with manageable inventory levels and ethical materials like FSC-certified wood. Balancing small initial orders with a clear scaling plan helps maintain cash flow while testing consumer demand. Sourcing diverse products through mixed SKU strategies keeps the storefront fresh without overcommitting to a single design.

Long-term growth depends on transitioning from air freight to sea transport as volumes increase to lower per-unit costs. Establishing a private label identity through sustainable sourcing and reliable payment terms secures a competitive spot in the 2026 market. Successful shop owners prioritize verified certifications and supply chain stability to turn a small niche boutique into a scalable retail business.

Frequently Asked Questions

What is the standard MOQ for custom handcrafted orders?

Minimum Order Quantities vary by complexity, typically ranging from 50 to 500 units for simple items and up to 5,000 units for highly customized manufacturing. We set a standard MOQ of 300 pieces for OEM and ODM products to support brands entering the market.

How can small businesses source affordable crafts?

Small businesses access affordable pricing through tiered wholesale structures. International sourcing offers significant savings with 8-12 week lead times, while domestic options provide faster 2-5 day delivery. Sourcing from mills often requires 500-1,000 yards per color for fabric-based items.

Are PayPal and credit card payments supported?

Yes, we accept PayPal which facilitates payments via credit cards like Visa, Mastercard, and American Express. Standard commercial terms require a 30% deposit upon order confirmation, with the remaining balance due at the time of shipment.

What shipping options are best for small orders?

Small parcel shipping via carriers such as UPS, FedEx, or USPS is the standard for individual packages under 150 lbs. For larger batches exceeding 150 lbs, Less Than Truckload (LTL) palletized shipping offers a more cost-effective logistics solution.

Can I use supplier photos on my e-commerce website?

Suppliers generally own the copyright for their product photography. While we offer high-resolution images of at least 800×800 pixels to ensure zoom functionality for retailers, you must obtain explicit permission before using these materials on your platform.

Does the manufacturing process support business scaling?

The production framework supports growth by allowing brands to start with 300 pieces and scale to 3,000 units or more. We provide FSC-certified materials and multi-stage quality control to maintain consistency as order volumes increase.