B2B buyers selecting decorative bird carvings face a choice between the unique character of artisanal work and the industrial scalability of modern manufacturing. Selecting the wrong material or production method leads to structural failure or inconsistent batches that damage retail reputations and increase supply chain costs.

This guide breaks down the performance metrics of hand-carved wood versus CNC and resin alternatives. It covers how to maintain wood moisture content below 15% to prevent cracking, the ±0.001-inch precision of 5-axis CNC gantry systems, and the AQL Level II inspection standards required to keep defect ratios under 0.5% for global markets.

The Anatomy of a High-Quality Carving

In 2026, high-quality wood carving relies on three core pillars: material density, tool precision, and progressive finishing. Master artisans select specific woods like basswood or pinewood to ensure structural integrity while using specialized 60-degree V-tools and gouges. A systematic four-stage sanding process and protective oil application produce the refined, durable finish required for global retail markets.

Material Selection and Structural Integrity

Professional-grade carvings begin with wood species selected for their specific grain characteristics and density. Sourcing sustainable basswood provides a soft, uniform grain pattern that allows for clean, effortless cuts, making it ideal for foundational work.

Stability is maintained through strict moisture control protocols. By stabilizing wood fibers before and during the carving process, craftsmen prevent the warping or cracking that often compromises lower-quality wood products. This technical attention to material state ensures the finished sculpture retains its proportions and structural integrity long after it leaves the workshop, regardless of environmental shifts.

Technical Tooling and Surface Finishing Specifications

Precision in wood carving is achieved through the use of specialized tooling and specific geometry. Employing 60-degree V-tools creates the sharp grooves and defined lines necessary for professional aesthetics, while varying gouge sweeps establish realistic 3D textures and accurate proportions. Maintaining these tools with high-grit sharpening stones ensures every cut is crisp, reducing the risk of fiber tearing and minimizing the need for aggressive post-carving correction.

The final quality of a carving depends on a systematic surface finishing sequence. Sanding begins at 150 grit and progresses through 220, 320, and 400 grit to achieve a glass-smooth texture. Once the surface is prepared, protective oil or polyurethane coats are applied to seal the wood. A final rub with steel wool produces a durable, market-ready luster that highlights the natural grain while providing a barrier against environmental degradation.

Hand-Carved vs. CNC Machine

Hand-carving offers a unique, artisanal feel where no two pieces are identical, while CNC machining provides surgical precision with ±0.001-inch tolerances. For 2026 manufacturing, CNC provides the scalability and speed needed for bulk orders, maintaining 100% consistency across hundreds of units using advanced 5-axis gantry systems.

| Technical Metric | Hand-Carved | CNC Machining |

|---|---|---|

| Precision Tolerance | Variable (Human Error) | ±0.001 inches |

| Production Velocity | 2+ Weeks (12ft Sculpture) | 1 Week or Less |

| Scalability | Low (Natural Variations) | High (Digital Replication) |

| Geometry Capability | Organic Textures | Complex 5-Axis Undercuts |

Traditional Hand-Carving and Digital Reproducibility

Hand carving introduces natural variations in edge definition and surface texture that machines cannot mimic perfectly. Artisans use specialized hand tools to adapt to unique wood grain patterns and density in real-time, allowing for a tactile finish that feels organic. This method relies on the carver’s intuition to handle material defects or shifting humidity during the process.

CNC technology utilizes 5-axis gantry systems to follow digital 3D paths, ensuring the 100th unit matches the first without deviation. Digital programming allows for complex internal supports and deep undercuts that are difficult to reach with standard hand chisels. This digital reproducibility provides inherent quality assurance over manual methods, especially when scaling a single design for commercial environments.

CNC Precision Standards and Production Efficiency

CNC machining centers achieve precision tolerances of ±0.001 inches, eliminating human-induced dimensional errors. These automated systems run 25-50% faster than manual carving. By removing the dependency on continuous manual effort, production facilities can focus on initial setup and material preparation.

High-speed 12-meter 5-axis spindles maintain structural integrity by applying uniform pressure across the material. Digital toolpaths also reduce wood waste and optimize material removal. This controlled approach improves moisture management during the carving process, as precise and repeatable cuts minimize the variations in wood exposure that typically cause warping in handmade pieces.

Wood vs. Polyresin/Plastic

Natural wood provides superior structural strength and traditional aesthetics for heavy-duty items, while polyresin composites like HDPE offer immunity to rot and moisture. Synthetic materials excel in high-humidity environments where they maintain color and integrity for over 15 years without the regular sanding or staining required for wood products.

Structural Composition and Material Integrity

Natural wood relies on a lignin matrix and cellulose fibers to deliver the mechanical strength required for large-scale structures. Glass fibre-reinforced plastic (GRP) uses unsaturated polyesters or epoxy resins to achieve elasticity levels comparable to natural timber. Wood usually supports heavier loads and permits larger panel spans without sagging, whereas polyresin formulations replicate wood’s density while providing a non-porous barrier against liquid penetration.

Environmental Performance and Maintenance Lifecycle

Marine-grade polyethylene and recycled HDPE offer a service life exceeding 15 years by resisting rot, mildew, and pest infestations. Polyresin products integrate UV-stable pigments during manufacturing to ensure the color remains consistent despite heavy sun exposure. Natural wood demands periodic applications of sealants or stains to prevent warping and swelling in humid climates. These synthetic alternatives also provide a splinter-free surface and tend to stay cooler than dark-stained wood in outdoor settings.

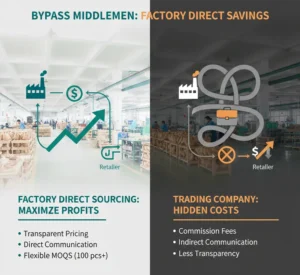

Premium Hand-Carved Wooden Birds at Factory-Direct Prices

Avoiding Cracks: Moisture Control

Wood integrity depends on maintaining internal moisture content below 15% and ambient relative humidity between 30% and 60%. Following ANSI/IICRC S500-2021 standards, any moisture intrusion requires a 48-hour response window for drying to prevent permanent warping, splitting, or mold growth in handcrafted carvings.

| Moisture Metric | Technical Threshold | Regulatory Standard |

|---|---|---|

| Relative Humidity (RH) | 30% – 60% | EPA Guidelines |

| Wood Moisture Content | < 15% WME | Material Stability |

| Drying Response Window | < 48 Hours | ANSI/IICRC S500-2021 |

| Dew-Point Temperature | < 60°F | ASHRAE 62.1-2022 |

Principles of Relative Humidity and Wood Stability

Maintaining indoor relative humidity (RH) within the 30-60% target range prevents the physical fiber contraction and expansion that leads to structural failure. When humidity levels swing wildly, wood cells experience mechanical stress, resulting in visible surface checks and deep splitting. Keeping the wood moisture content (WME) strictly below 15% eliminates the persistent dampness that softens wood fibers and encourages degradation.

Environmental monitoring must include tracking dew-point levels to ensure they stay below the 60°F threshold. This precaution reduces the risk of surface condensation, which serves as a primary catalyst for mold colonization on intricate carvings. Controlling these environmental fluctuations stops the rapid stress cycles that often cause structural splitting in natural basswood and other sensitive materials.

Technical Standards for Monitoring and Climate Regulation

Adhering to ANSI/IICRC S500-2021 protocols requires restoring moisture-impacted materials within a 48-hour drying window. This rapid response prevents secondary damage and mold growth. Proper facility management involves implementing HVAC settings compliant with ANSI/ASHRAE Standard 62.1-2022 to regulate humidity throughout all manufacturing and storage phases. These settings ensure stable conditions regardless of seasonal external shifts.

Using moisture meters and psychrometric logging provides the daily data necessary to verify material safety. These tools track temperature and material moisture levels to identify potential risks before they cause physical damage. Applying the three EPA moisture control principles—liquid water barriers, condensation prevention via airflow, and the use of moisture-tolerant materials—creates a robust defense against environmental decay in wood products.

The Importance of Hand-Painting

Hand-painting allows artisans to adapt to wood grain variations and moisture levels in real-time, using PDCA Standard P5 benchmark samples to define quality. This manual process ensures better adhesion and color depth than automated lines, especially when managing multi-component paints with a limited three-hour pot life.

Manual Application and Surface Preparation Benchmarks

Artisans use PDCA Standard P5 to establish benchmark samples that define the achievable quality for each wood carving series. These physical samples act as the definitive reference point for surface preparation and coating systems, ensuring the final product matches the approved aesthetic and technical specs. Manual surface preparation includes the cotton pad rub test to detect residual oils or dirt that automated cleaning systems frequently overlook. If the pad shows black marks, the technician re-cleans the surface to prevent adhesion failure.

Hand-painting provides the flexibility to make immediate adjustments to paint viscosity based on real-time RheoStream FC measurements and ambient humidity. This responsiveness prevents issues like sagging or uneven film build that occur when environmental conditions shift. Technicians also perform sanding tests to measure the surface roughness of base coatings. This ensures the substrate maintains the correct profile for the final decorative layer to bond securely to the basswood.

Technical Metrics for Color and Coating Durability

We apply PDCA Standard P6 criteria to determine the final acceptance of all painted surfaces before they leave the workshop. This standard provides a clear framework for inspecting the finish under specific lighting conditions to identify any non-conformance. To ensure bulk orders remain uniform, spectrophotometer testing monitors color consistency. This process keeps color variations within strict delta-E limits, providing a level of precision that visual inspection alone cannot guarantee.

Manual mixing protocols are essential for managing multi-component paints under MIL-PRF-85285 specifications. Since these high-performance coatings often have a pot life limited to three hours after mixing, artisans work in small batches to ensure the paint remains chemically active during application. Quality teams verify long-term durability through abrasion and alkali resistance tests following ASTM International standards. These metrics confirm the coating will withstand cleaning chemicals and physical wear in 2026 market environments.

Spotting Defects in Bulk Orders

Retailers identify defects by applying AQL Level II standards across three production phases: pre-production, during-production, and pre-shipment. Using the 1-10-100 rule, businesses focus on early detection to avoid costs that increase tenfold at each supply chain stage, maintaining defect ratios below 0.5% for high-precision goods.

Inspection Metrics and Detection Timing

Quality teams establish a production baseline by calculating the Defect Rate, which involves dividing defective units by the total units produced and multiplying by 100. This metric provides the raw data necessary to identify systemic failures in the assembly line. To prevent these errors from compromising an entire batch, manufacturers implement During-Production Inspection (DUPRO). This phase utilizes Statistical Process Control to monitor real-time outputs and flag deviations from the approved gold sample.

As the order reaches 80% completion, inspectors conduct Pre-Shipment Inspections to verify that the final goods comply with AQL Level II standards. This final gate ensures that packaging, labeling, and functional specs meet the purchase order requirements before the cargo leaves the factory. To measure the success of these checkpoints, businesses apply the Defect Escape Rate formula, which compares customer-reported issues against defects caught internally to identify gaps in the inspection protocol.

Industry Benchmarks and Economic Impact

The financial incentive for rigorous inspection follows the 1-10-100 rule. A defect costing $1 to fix during the initial production phase scales to a $100 loss if the issue reaches the end consumer. For high-stakes sectors like consumer electronics, the 2026 industry benchmark requires defect ratios to remain under 0.5%. Staying below this threshold minimizes warranty claims and protects brand reputation in competitive markets.

Standardizing quality data requires normalization to account for different manufacturing complexities. Teams track defects per 100 components or per production hour to ensure fair comparisons between simple and high-density assembly lines. In specialized fields such as aerospace or defense, suppliers must go further by adopting AS9102 documentation standards. These protocols require first-article inspections and precise tolerance mapping to ensure every unit meets safety-critical certifications.

Our QC Guarantee

Our quality guarantee relies on a multi-stage system anchored by ISO 9001:2015 standards. We combine real-time Statistical Process Control (SPC) with rigorous pre-shipment inspections at 80% production completion, ensuring every wood product meets international safety and durability requirements for global retail markets in 2026.

ISO-Certified Management Systems and Safety Standards

We implement ISO 9001:2015 quality management systems to document procedures and verify compliance across the entire production line. This framework establishes clear requirements for process organization and product conformity. Our auditors follow ISO 19011:2018 guidelines to evaluate management systems and audit programs, ensuring high-level oversight and continuous improvement.

We maintain international safety and ethical certifications including FSC for wood sourcing, BSCI for manufacturing ethics, and EN71-1/-2/-3 for product safety. Integrating Total Quality Management (TQM) and Lean practices helps us eliminate waste and maintain consistency in large-scale OEM orders. These standards ensure that every unit produced meets the ethical and safety expectations of global distributors.

Technical Monitoring and Three-Stage Inspection Protocols

Our technical team utilizes Statistical Process Control (SPC) and the 7 Quality Tools, such as Pareto charts and fishbone diagrams, to identify root causes of defects. We monitor real-time data through control charts to detect production trends and prevent nonconformity before products leave the facility. This data-driven approach allows for immediate corrective actions during the manufacturing cycle.

A mandatory Pre-shipment Inspection (PSI) occurs when production reaches 80% completion. We use random batch sampling to verify that the final goods meet all established standards and client specifications. To ensure material durability, we apply strict humidity control protocols for basswood to prevent cracking.

Final Thoughts

Choosing between hand-carved wood and synthetic resin depends on the specific environment and scale of a project. Hand-carving delivers unique textures and artisanal character that machines cannot fully replicate, while CNC machining offers the sub-millimeter precision needed for high-volume commercial consistency. Resin and HDPE composites provide a durable alternative for humid settings where natural wood might warp or rot. Selecting the right production method ensures the finished piece balances visual appeal with long-term performance.

Reliable quality comes from strict adherence to technical standards and proactive moisture management. Implementing ISO-certified protocols and AQL inspections at multiple production stages catches defects before they reach the supply chain. Buyers who focus on these verified metrics—from wood moisture content to paint adhesion benchmarks—secure products that withstand environmental stress and heavy use. Investing in these manufacturing safeguards protects brand reputation and ensures every unit meets the requirements of the 2026 retail market.

Frequently Asked Questions

Are the wood products truly hand-carved?

Items qualify as hand-carved when artisans use manual tools and specialized techniques rather than high-volume mechanized methods. Our process aligns with TESDA Wood Carving Level II competencies and GNBS standards, ensuring each piece relies on individual craftsmanship for furniture elements and decorative sculptures.

What quality control standards do you follow?

We manage production through ISO 9001:2015 quality management systems and Six Sigma methodologies. This technical framework targets a precision of 3.4 defects per million opportunities to maintain high consistency across bulk orders.

How are defective goods handled under AQL standards?

We classify defects into critical, major, and minor categories based on Acceptable Quality Limit (AQL) standards. We typically apply a 2.5% AQL for major defects; if sampled items exceed these tolerances during inspection, the entire batch faces rejection.

How does the cost of wood compare to resin products?

Resin alternatives are generally 20–40% less expensive upfront, typically ranging from $800 to $2,500, whereas wood products range from $1,000 to over $4,000. While resin requires less maintenance, wood provides a longer lifespan of 20 or more years when properly sealed.

Can a pre-shipment inspection be conducted?

Yes, pre-shipment inspections (PSI) occur once production reaches the 80% completion threshold. We use ISO 2859-1 sampling plans to verify quantity, dimensions, and packaging safety against your specific requirements before the order leaves the factory.