Modern interior design shifted from flat surfaces to tactile, light-reactive installations that redefine commercial and residential spaces. Bird wall art and decor meet this demand by using 3D flock configurations that extend 2 to 5 inches from the wall, creating dynamic shadows that change throughout the day. For B2B buyers and designers, these pieces offer a way to combine natural aesthetics with engineered precision, ensuring every installation remains safe and visually striking.

This article details the technical specifications necessary for professional-grade decor, from 1 mm minimum material thickness for structural integrity to NFPA 286 fire safety compliance. You will find insights into color matching using precise HEX codes and the benefits of sourcing FSC-certified sustainable basswood for large-scale projects.

The Rise of 3D Wall Art

3D wall art represents a shift from flat decoration to textured, light-reactive installations. In 2026, designers prioritize additive manufacturing to achieve complex geometries, adhering to 1 mm minimum thickness for plastics and NFPA 286 safety standards to ensure durability and building code compliance.

Transition from Flat Surfaces to Tactile Geometry

Interior design trends for 2026 emphasize multisensory environments. These spaces use physical depth to create dynamic shadow play that changes as ambient light moves across the surface. Designers now employ algorithmic patterns and complex lattice structures that exceed the capabilities of traditional hand-carving. Scalable ODM manufacturing processes allow these intricate tactile designs to enter the market efficiently, meeting the demand for custom architectural decor at scale.

Engineering Standards for Structural Integrity

Technical precision ensures that 3D installations remain durable and safe. Manufacturers maintain a 1 mm minimum wall thickness for materials like Nylon PA12 and PLA to prevent structural failure during transport and handling. Stainless steel components require a thickness between 1.5 mm and 2 mm for protrusions to ensure long-term stability. Beyond physical strength, modular 3D wall panels must adhere to NFPA 286 fire safety standards to meet strict interior building codes. Using tolerances of ±0.3 mm ensures that tiled configurations fit together seamlessly, creating a unified appearance across large wall surfaces.

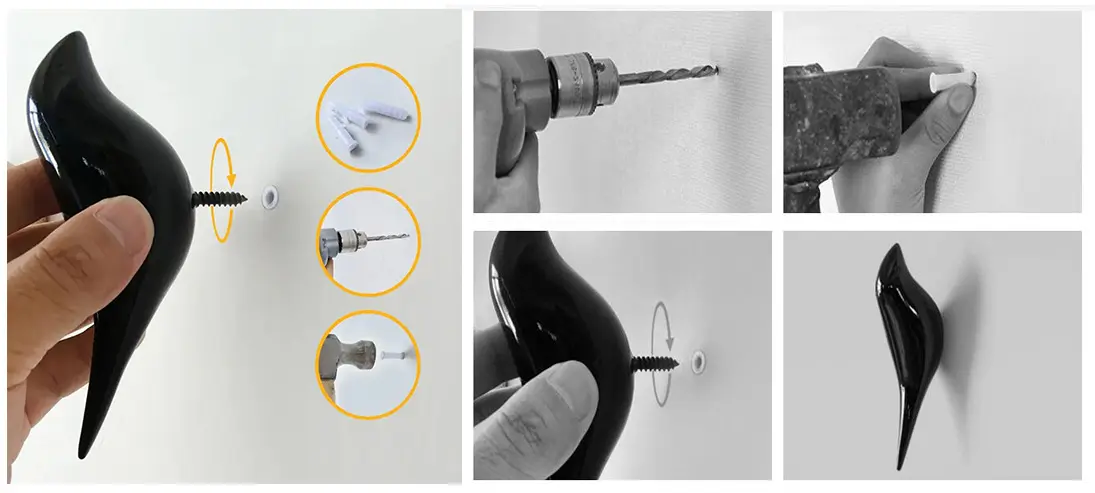

Installation Methods (Adhesive vs. Nail)

Professional installations in 2026 rely on mechanical fasteners like corner bolts and tensioned cables rather than adhesives to ensure permanent stability. While adhesives work for small items, heavy-duty displays require 5/64″ steel cables and surface-specific anchors to support a 52-pound breaking strength per strand.

| Surface Type | Hardware Solution | Installation Standard |

|---|---|---|

| Masonry & Brick | Expanding net bolts & split pins | 52 lb breaking strength |

| Wood Structures | Screw eyes & spade screws | 3-4 foot spacing |

| Steel I-Beams | Girder clips (no-drill) | High-tension perimeter |

| Stucco & Metal | Kwik togs & eye loops | 2-foot max interval |

Mechanical Fasteners for Permanent Structural Integrity

Mechanical systems utilizing 5/64″ galvanized or stainless steel cables provide a consistent breaking strength of 52 pounds per strand. Installers use turnbuckles and crimping tools to create high-tension setups that stay tight over long periods. These components prevent the sagging or movement common in less robust setups. Unlike adhesives or Velcro which often fail on porous stone or stucco, bolted hardware maintains its grip regardless of temperature shifts or environmental moisture.

Securing hog ring loops at every mesh interval ensures the art remains taut and properly aligned with the perimeter cable. This method creates a “tight-as-a-drum” finish that prevents gaps or structural failure. Using specialized tools like the BirdBuster crimping system allows for uniform tension across the entire surface, ensuring the installation handles wind loads and vibrations without losing its shape.

Surface-Specific Hardware and Tensioning Standards

Technicians select fasteners based on the specific material of the mounting surface to ensure safety and longevity. Expanding net bolts and split pins secure heavy installations into masonry, brick, and concrete walls by creating a physical anchor within the substrate. For wooden structures, screw eyes and spade screws offer reliable grip points. Steel I-beams require girder clips, which attach firmly to the flange without the need for drilling or compromising the structural steel.

Intermediate attachments play a critical role in weight distribution, requiring placement every 2 to 4 feet to prevent cable bow-out. This spacing varies depending on the bird species targeted; smaller birds like sparrows require closer intervals of 2 feet or less, while pigeon-deterrent setups use 3 to 4-foot gaps. Hollow surfaces like stucco or sheet metal utilize Kwik togs with eye loops to provide specialized load-bearing support that standard screws cannot offer.

“Flock” Configurations

“Flock” configurations feature multi-bird sculptural arrangements that create a sense of motion. These 3D pieces typically extend 2 to 5 inches from the wall and use varying projections to mimic natural flight patterns. They serve as focal points in large spaces, offering visual depth through layered groupings of metal or resin birds.

Dimensional Layouts and Visual Depth

Large-scale arrangements often incorporate over 20 individual birds within a single piece to simulate realistic flight patterns. These layouts maximize visual impact by using staggered depth levels between 2.5 and 4.8 inches. This variation in projection creates natural shadows that change based on room lighting, which adds a three-dimensional quality to the wall surface.

Dimensions vary to accommodate different residential spaces. Expansive pieces reach sizes such as 69″L x 22″H or 48″W x 23″H, allowing the art to cover significant horizontal area. These configurations prioritize aesthetic layering, placing birds at different lengths and angles to suggest active movement rather than a static display.

Material Properties and Mounting Specs

Manufacturers utilize resin composites and lightweight metals to keep total product weights between 2.4 and 12 lbs. This specific weight range ensures the pieces remain compatible with standard wall hooks, removing the need for specialized engineering or heavy-duty anchors. Metal variants provide high durability for indoor environments, while matte resin finishes offer a textured, artisan appearance.

Production standards for upcoming 2026 projects involve specific manufacturing requirements. For instance, Jilin Ever Creation maintains a 300-piece minimum order quantity for custom bird shapes or unique color palettes. These items ship in protective cartons to safeguard the delicate bird projections and maintain the structural integrity of the flock arrangement during transit.

Bring Nature to Life with Premium Hand-Carved Wooden Crafts

Color Palettes (Natural vs. Painted)

Bird wall art in 2026 balances high-fidelity naturalism with custom interior design. Natural palettes replicate exact plumage HEX codes from species like the Galah or Golden pheasant. Alternatively, painted palettes use soft earth tones or monochromatic schemes to match specific room decor, often utilizing Giclee printing on 1.5-inch deep archival canvases for lasting color.

Natural Species Plumage and HEX Fidelity

Authentic bird art relies on precise color matching to replicate the organic brilliance found in nature. For example, artists use HEX codes like #46159C Purple and #62B4B1 Teal to capture the iridescent feathers of the Sparkling Violetear. The Galah requires Orchid Pink (#E578B2) and Raspberry (#B4315A) to maintain biological accuracy. These specific values ensure that the final print reflects the actual species rather than a generalized interpretation.

The Golden pheasant provides a palette of Crimson Red (#A91501) and Goldenrod (#BA8A04), while the Keel-billed toucan introduces vibrant Burnt Orange (#AC5501) and Chartreuse Yellow (#DFE03D). For homeowners seeking neutral tones, the Barn owl offers a sophisticated mix of Dark Coffee (#312723) and Silver Gray (#BABDC2). This level of detail creates a realistic visual experience that anchors the room with organic authenticity.

Painted Palettes and Giclee Print Specifications

While naturalism focuses on accuracy, painted or abstract palettes prioritize interior harmony. Designers apply soft blues, greens, and muted earth tones to evoke a calming atmosphere suitable for modern living spaces. Monochromatic schemes, such as a black-and-white Snowy Owl, emphasize feather textures and visual contrast. These choices allow the art to blend seamlessly with existing furniture, curtains, or wall colors without sacrificing the subject’s essence.

The Giclee printing process supports these varied palettes through high-resolution inkjet technology. This method uses multiple ink colors to achieve a wide gamut on archival substrates, preventing the colors from fading over time. Most professional bird wall art follows a standard size of 24″ x 24″ x 1.5″ deep. This depth provides structural durability and a gallery-style presence, making it suitable for both indoor and outdoor displays.

For Interior Designers: Specs

Professional designers select bird wall art based on material durability and safety ratings. Key specifications include tempered glass that is ten times stronger than standard options and hardware rated for 5-10 lbs. Adherence to FSC and ISO 9001 standards ensures sustainable sourcing and consistent quality for commercial and residential interiors.

| Material Feature | Technical Data | Compliance Standard |

|---|---|---|

| Tempered Glass | 10x Impact Resistance | Shatter-Safety (Blunt fragments) |

| Weight Capacity | 5 – 10 lbs Load Rating | Substrate-dependent mounting |

| Structural Core | Sustainable Basswood | FSC, ISO 9001, EN71-1/-2/-3 |

Material Durability and Safety Standards

Tempered glass components provide ten times the impact resistance of standard glass. These panels shatter into small, blunt fragments if broken, which minimizes injury risks in high-traffic commercial or residential environments. Sustainable basswood sourcing meets FSC certification requirements for 2026 environmental standards. Manufacturing processes follow ISO 9001 and EN71-1/-2/-3 protocols to guarantee chemical safety and structural consistency across all units.

Load Ratings and Installation Requirements

Standard mounting hardware supports decor weights between 5 and 10 lbs depending on the wall substrate. Pre-installed brackets and pre-drilled holes align with heavy-duty screws and hooks to ensure secure permanent placement. Adhesive strips and wall putty provide damage-free alternatives for lightweight displays on smooth surfaces, allowing for design flexibility without surface degradation.

Packaging for Wall Art

Safe artwork transport requires a multi-layered approach using acid-free archival tissue and specific cushioning clearances. For 2026 shipping standards, practitioners use foam board sandwiches for framed pieces and dual-orientation bubble wrap for canvases, ensuring at least three inches of box clearance to prevent impact damage.

Layering Protocols for Surface Integrity

Protecting the delicate surface of wall art begins with a primary barrier. Technicians wrap canvas surfaces in acid-free archival tissue or glassine to prevent static damage and chemical reactions that occur with standard papers. This specific material choice ensures the painting remains pristine without the risk of the wrapping adhering to the medium or leaving unwanted residue.

Impact protection requires two layers of bubble wrap applied in alternating horizontal and vertical orientations. Securing these layers with masking tape at the rear of the piece prevents the wrapping from shifting during movement. Keeping bubble wrap away from direct contact with the canvas surface is a critical requirement, as the plastic can transfer its texture or trap moisture against the paint, causing permanent surface alterations.

Framed works with glass components utilize a masking tape X-pattern across the exterior surface. This configuration contains glass shards if a break occurs, shielding the underlying artwork from scratches. This method provides a necessary safety layer for the transit of glazed pieces, ensuring the structural stability of the glass panel under pressure.

Dimensional Standards and Structural Support

Structural reinforcement for shipping involves a foam board sandwich technique. Creating a rigid shell that measures 2 inches larger than the artwork on all sides effectively immobilizes the piece within its package. This unit then rests inside a shipping box that maintains a minimum 3-inch clearance on all sides, filled with shredded white paper or high-density bubble wrap to act as a buffer against external vibrations.

Rolled canvases require heavy-duty mailing tubes with diameters ranging from 8 to 12 inches to prevent permanent deformation or cracking of the paint. An internal support tube keeps the rolled material from collapsing inward. For frames exceeding 30 inches, telescopic boxes provide the necessary structural rigidity, while custom wooden crates with plywood reinforcement are necessary for any items weighing over 5 lbs.

Modern shipping standards prioritize stable cushioning over traditional fillers. Stable materials replace Styrofoam peanuts, which tend to break down under pressure and lose their protective properties. High-quality cushioning ensures the artwork remains centered in the container, preventing the shifting that typically leads to edge and corner damage during long-distance logistics.

Final Thoughts

Integrating three-dimensional bird sculptures into a room changes how light and shadow interact with wall surfaces. These pieces move away from flat images and use tactile geometry to create physical depth that shifts as ambient light moves throughout the day. Choosing materials like sustainable basswood or impact-resistant tempered glass ensures the art remains durable while meeting essential safety codes. This shift toward textured, light-reactive installations reflects a growing preference for dynamic and multisensory living spaces.

Maintaining the visual impact of these arrangements requires a focus on professional installation and routine care. Using mechanical fasteners and tensioned cables provides the stability needed for large-scale flock configurations, preventing the sagging often seen with simple adhesives. Regular biweekly dusting and consistent climate control preserve the intricate colors and structural integrity of the materials. Following these technical standards and maintenance protocols ensures that detailed bird wall art remains a stable and vibrant focal point for years.

Frequently Asked Questions

How do these decorative pieces attach to the wall?

They bolt specialized hardware like corner bolts and turnbuckles directly into the wall instead of using adhesives. Technicians space cables every 2 to 4 feet depending on the bird size and tension them until they are tight.

Will the wall art fall off over time?

No. These items weigh between 0.18 and 8.5 lbs, which makes them light enough for standard wall mounting. Proper installation with integrated back hardware ensures they remain fixed and stable under normal indoor conditions.

Are bird sets available in specific quantities?

Yes. Most collections include sets of 3 or 5 birds. Popular options include 6-inch and 8-inch brass hangings or ceramic sparrow sculptures intended for grouped displays.

What packaging standards ensure safe delivery?

Shippers use double-walled corrugated cardboard boxes sealed with the H-taping method. The high-performance polyethylene foam in the packaging supports a static load of 0.70 kg/cm².

Is it possible to order custom colors?

Yes. Manufacturers use high-resolution printing on tempered glass, which is ten times stronger than standard glass. You can select from specific palettes like Gold, Aqua Blue, and Cracked Pepper or provide custom images to match a specific interior design.