Retailers and wholesale buyers face increasing pressure from global mandates like the Corporate Sustainability Reporting Directive (CSRD), which makes environmental metrics as vital as financial audits. To reach 20% carbon reduction targets by 2026, brands need materials that offer both visual appeal and clear, verifiable supply chain tracking. Moving beyond voluntary green initiatives is now a necessity for staying compliant and maintaining consumer trust in a competitive market.

We analyze why basswood (Tilia) works as a reliable choice for sustainable decor, balancing a lightweight profile of 26.0 lbs/ft³ with a 410 lbf Janka hardness rating for detailed carving. This guide covers FSC-certified sourcing protocols, the importance of zero-VOC paints for indoor air quality, and a direct performance comparison between natural timber and synthetic resin alternatives. By understanding these technical specifications, businesses can make informed decisions that support both circular economy goals and long-term product durability.

The Shift to Sustainable Retail

Retailers are transitioning to circular models and carbon-neutral operations driven by strict global directives and consumer demand for transparency. By 2026, brands integrate verifiable supply chain tracking and sustainable materials like FSC-certified wood to meet 20% carbon reduction targets.

Regulatory Mandates and Disclosure Standards

New legal frameworks force retailers to move beyond voluntary green initiatives toward standardized environmental disclosure. The Corporate Sustainability Reporting Directive (CSRD) requires brands to provide granular data on carbon emissions, energy consumption, and waste management. This mandate ensures accountability across the organization by making sustainability metrics as critical as financial reporting.

The Corporate Sustainability Due Diligence Directive (CSDDD) focuses on supply chain integrity. Companies must identify and mitigate human rights and environmental risks throughout their entire production network to avoid significant fines and reputational damage. Extended Producer Responsibility (EPR) laws add further complexity by requiring retailers to verify the recyclability and compostability of their packaging based on regional collection systems.

Circular Material Targets and Resource Efficiency

Operational strategies prioritize circularity and the measurable reduction of resource footprints. Many retailers set goals to integrate at least 50% sustainable materials into their product lines while aiming for a 20% reduction in carbon emissions over a five-year window.

Material selection for physical infrastructure also undergoes scrutiny. Standardizing the use of FSC-certified wood for store fixtures ensures timber originates from responsibly managed forests. Retailers implement AI-driven energy optimization and IoT systems for real-time resource monitoring to support these targets.

What is Basswood (Tilia)?

Basswood, derived from the Tilia genus, is a soft-textured hardwood prized for its lightweight profile and fine, straight grain. It typically grows to heights of 130 feet and offers a creamy, pale aesthetic. Its unique physical properties make it the primary choice for intricate hand-carvings and high-quality sustainable wooden decor.

Physical Characteristics and Botanical Identity

Tilia americana, commonly known as American basswood, linden, or lime wood, originates from eastern North American forests. Mature trees reach heights between 65 and 130 feet with trunk diameters measuring up to 4 feet in primeval environments. The wood features a creamy white sapwood that transitions into a pale brown heartwood with a fine, even texture. Straight grain patterns provide a moderate luster that enhances the appearance of finished handcrafted items without the need for heavy staining.

Technical Specifications and Material Performance

The material averages a dried weight of 26.0 lbs/ft³ (415 kg/m³), offering a lightweight profile that improves shipping efficiency for large-scale decor. A Janka hardness rating of 410 lbf (1,820 N) ensures the wood remains soft enough for intricate manual carving while maintaining sufficient durability for indoor applications. Mechanical properties include a modulus of rupture of 8,700 lbf/in² and an elastic modulus of 1,460,000 lbf/in². Shrinkage values of 6.6% radial and 9.3% tangential indicate stable performance once the seasoning process finishes.

FSC Certification & Sourcing

FSC certification ensures wood products originate from responsibly managed forests through the Chain of Custody (CoC) standard FSC-STD-40-004. By 2026, this framework incorporates strict traceability and risk assessments, including the FSC-STD-01-004 module, to guarantee that materials like basswood are harvested legally and ethically.

| Standard Code | Primary Focus | Key Requirements |

|---|---|---|

| FSC-STD-40-004 | Chain of Custody (CoC) | Material sourcing, transfer systems, and volume control. |

| FSC-STD-01-004 | EUDR Compliance | Due diligence, risk assessment, and geolocation tracking. |

| FSC-STD-50-001 | Trademark Usage | Rules for on-product labels and promotional materials. |

Chain of Custody and Material Traceability

Certified organizations implement FSC-STD-40-004 V3-1 to manage the entire lifecycle of wood materials, from initial purchase to final sale. This process begins with the rigorous verification of supplier certificates to confirm that every input originates from an approved source. Manufacturers use a transfer system to physically separate certified wood from non-certified stock, preventing any accidental mixing during the production of wooden crafts or components.

To maintain the integrity of the supply chain, companies establish volume control balances. These records track the quantity of material purchased, the volume used in production, and the resulting wastage rates across all product groups. This transparent accounting ensures that the amount of certified product sold never exceeds the amount of certified material available. Furthermore, certification bodies follow FSC-STD-20-001 requirements to perform impartial audits, verifying that these internal controls function correctly and meet global sustainability benchmarks.

Compliance Modules and Labeling Standards

Regulatory updates have introduced the FSC-STD-01-004 module, which helps manufacturers meet EUDR (European Union Deforestation Regulation) due diligence requirements. This voluntary add-on requires organizations to conduct deep risk assessments and maintain detailed supply chain documentation, particularly for materials sourced from regions classified as high-risk. By integrating geolocation data and harvesting timestamps, the framework provides the transparency needed to prove that wood harvesting does not contribute to forest degradation.

Product claims follow the classification system defined in FSC-STD-40-004a V2.0, which distinguishes between FSC 100%, FSC Mix, and FSC Controlled Wood. Manufacturers apply trademarks to finished products according to FSC-STD-50-001, ensuring that labeling accurately reflects the material composition. This system supports various sourcing configurations, including small or low-intensity managed forests (SLIMF) and group certifications, allowing a diverse range of suppliers to participate in the certified market while maintaining strict ecological standards.

Premium Hand-Carved Wooden Birds for Your Wholesale Needs

Non-Toxic Paints & Finishes

Non-toxic paints and finishes rely on zero or ultra-low VOC formulations that eliminate hazardous chemicals like carcinogens and reproductive toxins. By 2026, industry standards require third-party certifications such as Green Seal GS-11 and Environmental Performance Rating (EPR) 3 to ensure these coatings maintain indoor air quality and meet global safety benchmarks for consumer goods.

Zero VOC Limits and Chemical Safety Requirements

Interior paints and primers used in high-quality woodcrafting must adhere to zero Volatile Organic Compound (VOC) limits. Formulations such as the Mythic Classic Interior MP 100 and MP 300 series meet these requirements by maintaining a chemical profile free of detectable VOCs. These safety standards involve a strict prohibition of hazardous substances, including triphenyl tins, tributyl tins, and phthalates like diethyl or dimethyl compounds. To align with Green Seal GS-11 and GS-47 benchmarks, coatings exclude all known carcinogens, mutagens, and reproductive toxins. While most additives are restricted, specific functional components like cobalt or manganese in wood stains are allowed only when kept below 0.06% by weight.

Technical Performance and Compliance Standards

Engineered finishes must achieve an Environmental Performance Rating (EPR) 3 to validate their safety and quality, as seen in the MP 720 high-hiding primers and MP 501 satin series. Regulatory compliance involves LEED EQ 4.2 and California 01350 chamber testing, which requires 90% of all interior surface areas to utilize certified low-emission products. For handcrafted items, adherence to EN71-3 safety standards ensures that toys and decorative carvings remain safe for all users. Durability remains a priority, with coatings undergoing rigorous testing on basswood substrates to confirm UV resistance, adhesion, and opacity according to MPI Green Performance Standards. These metrics ensure that eliminating toxins does not compromise the physical longevity or aesthetic quality of the wooden product.

Durability: Wood vs. Resin

Resin offers a maintenance-free lifespan of 15 to 30 years due to its resistance to moisture and UV exposure. Natural wood provides similar longevity of 20 or more years, but only if users perform consistent maintenance, such as resealing every two to three years to prevent warping and rot.

| Performance Factor | Resin (HDPE/Polypropylene) | Natural Wood (Treated/Cedar) |

|---|---|---|

| Expected Lifespan | 15 to 30 Years | 20+ Years (Strict maintenance) |

| Maintenance Needs | Low (Occasional washing) | High (Sealing/Staining every 2-3 years) |

| Primary Vulnerability | Extreme cold (brittleness) | Moisture, rot, and pests |

Material Resilience and Environmental Tolerance

Resin formulations using HDPE or polypropylene naturally resist mold, rust, and pest infestations without chemical treatments. High-quality UV20-rated resin components withstand 20,000 hours of direct sunlight exposure before showing signs of fading or structural degradation. In contrast, untreated wood remains susceptible to moisture absorption, which leads to warping and rot in humid or coastal climates. Pressure-treated wood provides a barrier against decay but maintains a higher risk of insect damage compared to synthetic alternatives.

Lifecycle Maintenance and Technical Constraints

Wood requires a strict maintenance schedule of painting, staining, or sealing every two to three years to reach its full potential lifespan. Resin products function as low-intervention solutions, requiring only occasional washing to maintain surface quality. Thermal performance varies significantly between these materials. Resin may become brittle in extreme cold, while wood maintains structural stability across wide temperature swings. Standard resin lacks the fire-retardant properties inherent in certain treated wood species, though it excels in resisting chemical corrosion and salt spray in maritime environments.

Marketing “Green” to Consumers

By 2026, green marketing shifts from vague descriptors to audited performance data. Brands build trust by utilizing certifications like FSC for sourcing and Greenguard for air quality. Providing specific metrics, such as VOC limits and lifecycle tiers, demonstrates an authentic commitment to environmental health and safety.

Third-Party Validation and Ethical Sourcing Standards

Brands secure credibility through rigorous independent audits that replace self-reported environmental claims. FSC certification remains the benchmark for wood products, requiring strict chain-of-custody tracking to prove materials come from responsibly managed forests. For cabinet manufacturers, the KCMA program evaluates several pillars including resource sustainability and waste minimization to verify environmental stewardship. Cradle to Cradle standards offer a holistic assessment of material health and renewable energy use within the supply chain, ensuring that ethical sourcing extends beyond simple origin stories to encompass social fairness and material reuse.

Quantifiable Metrics for Emissions and Lifecycle Impact

Technical proof of safety relies on meeting specific, industry-recognized benchmarks for indoor air quality and long-term performance. SCS Indoor Advantage Gold verifies that products comply with the California South Coast Air Quality Management District VOC limits, which are among the most stringent in North America. These metrics help consumers understand the physical impact of their decor choices on indoor air pollution, moving past generic “eco-friendly” labels toward physics-based data.

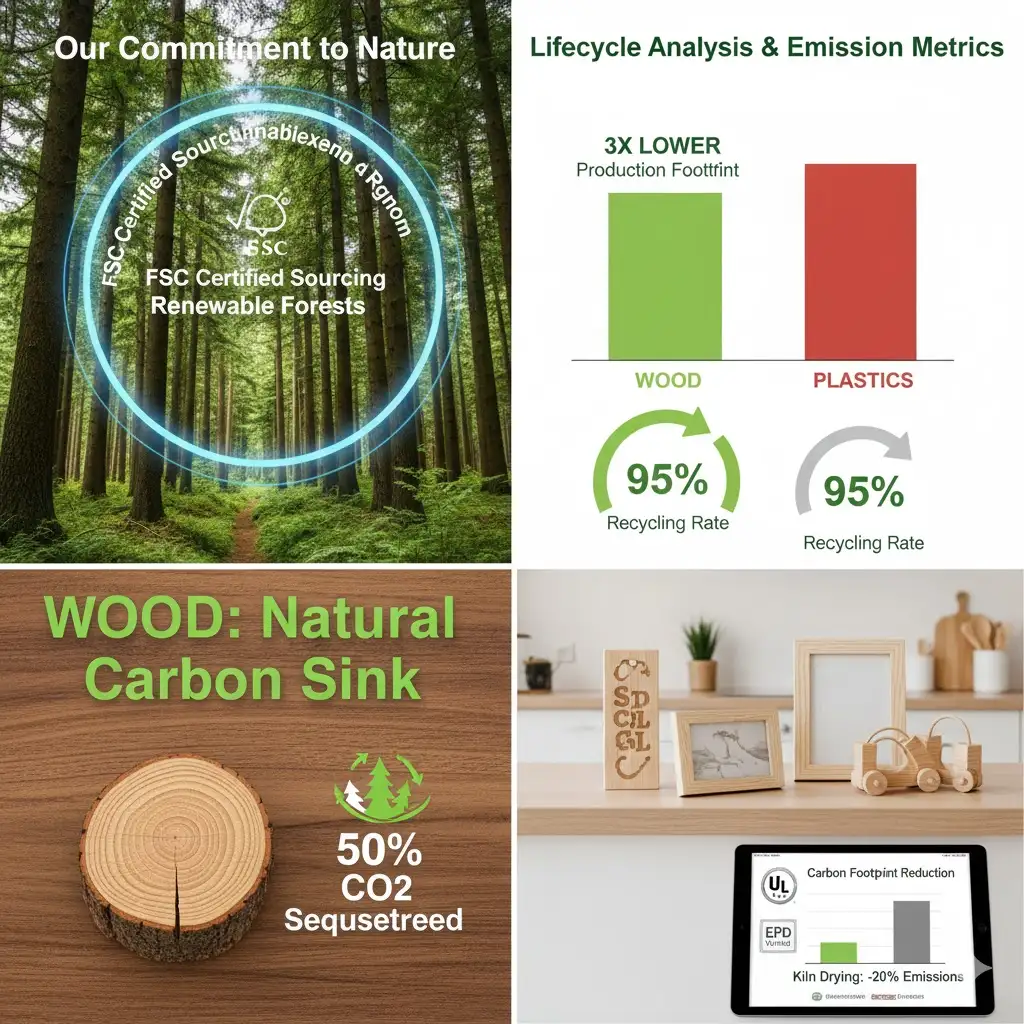

Our Commitment to Nature

Wood products function as natural carbon sinks, with 50% of their mass sequestering CO2. Compared to plastic alternatives, wooden decor reduces production footprints by up to 3x and maintains a 95% recycling rate, bolstered by FSC-certified sourcing from renewable forest regions.

Renewable Sourcing and Carbon Sequestration

Basswood sourced from the Changbai Mountain region serves as a renewable resource that supports consistent forest regeneration. Wood naturally sequesters carbon, with approximately 50% of its mass acting as a carbon sink throughout the product lifecycle. FSC certification validates that these raw materials meet rigorous international standards for biodiversity protection and ethical land use. Utilizing natural timber removes the petrochemical dependency commonly found in traditional plastic decor manufacturing.

Lifecycle Analysis and Emission Metrics

Lifecycle assessments show that plastic production generates a carbon footprint up to three times higher than wood for comparable retail display items. Research indicates that wooden materials achieve a 95% recycling rate, which significantly outperforms synthetic polymers in circularity. Specific heat-treatment processes, such as kiln or radio-frequency drying, reduce carbon footprints by 20% to 30% compared to chemical fumigation methods. Third-party verified Environmental Product Declarations (EPD) through UL confirm that wood manufacturing consumes less energy and releases fewer greenhouse gas emissions during the assembly of finished goods.

Final Thoughts

Choosing basswood helps retailers meet strict environmental targets while providing high-quality, handcrafted decor. This material stores carbon naturally and grows as a renewable resource, offering a functional alternative to synthetic resins. Brands that switch to these sustainable options align with upcoming regulatory changes and fulfill the growing demand for supply chain transparency.

Long-term growth in the wholesale sector relies on measurable sustainability and ethical production. Using FSC-certified timber and zero-VOC finishes lowers the environmental impact of retail displays and household items. When companies focus on material durability and waste reduction, they build a more resilient business model that meets the demands of a carbon-conscious market.

Frequently Asked Questions

Is basswood a sustainable choice for large-scale manufacturing?

Basswood is highly sustainable because it functions as a carbon sink during its 150-to-170-year lifespan. Kiln-dried basswood lumber has a carbon footprint of approximately 330 kg CO2-eq per cubic meter. It is also listed as a species of ‘least concern’ by the IUCN, making it an ideal renewable resource.

Does Jilin Ever Creation provide FSC certification for wood products?

Yes. We maintain valid FSC certification to ensure all timber originates from responsibly managed forests. Our manufacturing process also undergoes regular audits, maintaining BSCI, ISO9001, and EN71-1/-2/-3 compliance for global retail standards.

Are the paints and finishes lead-free and safe for home use?

We use finishes that meet strict safety standards, keeping lead content below the 0.009% threshold by weight set by the CPSC. Our paints comply with EN71-3 regulations, ensuring they are non-toxic and safe for both seasonal decor and novelty gifts.

How do you manage industrial wood waste during production?

Our facility uses industrial shredding and debarking drums to minimize wood loss to under 10%. We repurpose the remaining wood waste as biomass or compressed materials, ensuring the manufacturing cycle remains efficient and low-waste.

Does the packaging meet 2026 eco-friendly requirements?

Our packaging aligns with 2026 standards, targeting a 90% biodegradation rate within 60 days for compostable materials. We also enforce an 80% minimum fill rate for each shipping box to reduce unnecessary material use and optimize transport efficiency.