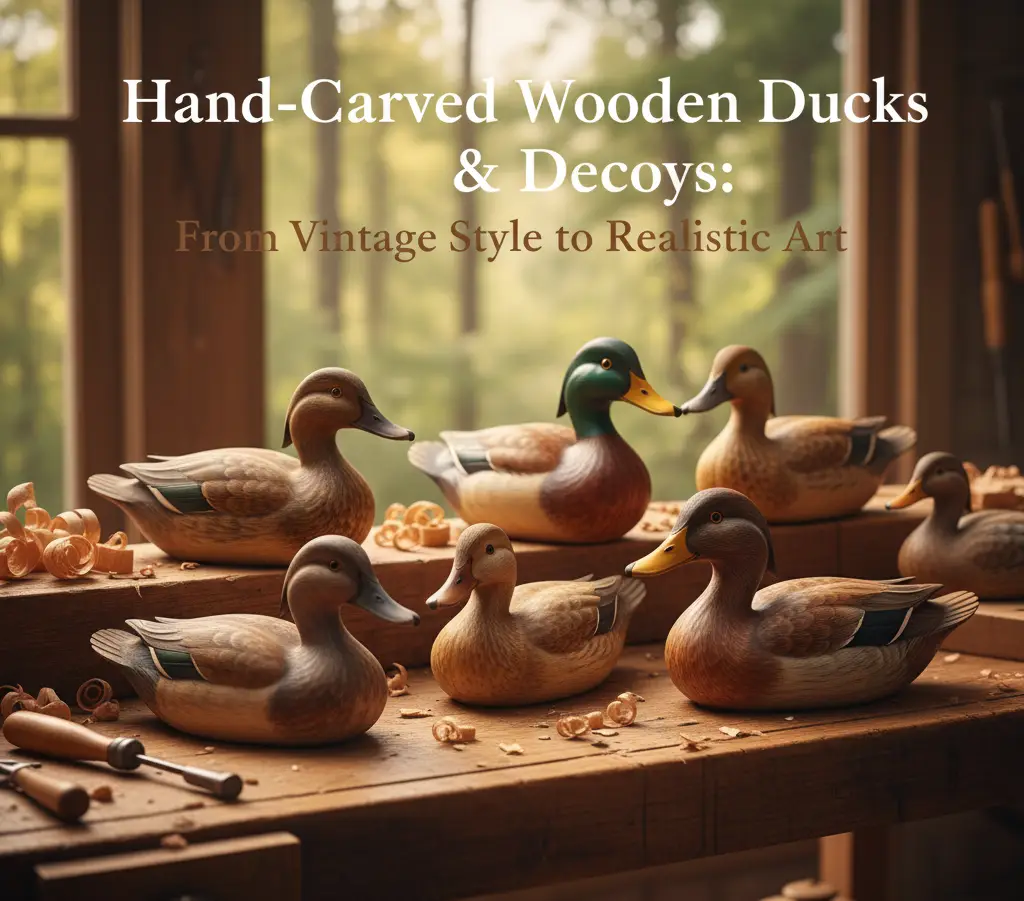

For B2B buyers and specialty retailers, the value of a duck decoy depends on a precise balance between historical craftsmanship and technical utility. Selecting the wrong material or finish can alienate serious collectors who look for regional authenticity or outdoor professionals who require field-tested durability.

This guide explores the evolution of waterfowl lures, covering sustainable basswood selection and multi-layered painting techniques. We analyze technical standards, including the 7.875-inch length that upright drakes require and the 6 to 7 hours of manual labor that artisans spend on a single piece. You will also find a breakdown of the differences between investment-grade antiques and modern wholesale options to help guide your procurement strategy.

The Legacy of Duck Decoys

Duck decoys evolved from functional hunting tools into highly valued art pieces and precision-engineered gear. Modern versions for the 2026 season prioritize exact anatomical replicas, such as 7.875-inch lengths for upright drakes, utilizing sustainable basswood or pine wood to ensure both durability and realism.

Historical Evolution of Waterfowl Lures

Early hunters crafted lures from natural reeds and local hardwoods to aid in food procurement. These utilitarian objects eventually shifted from simple survival tools into highly sought-after art. Artisans in the Changbai Mountain region continue to utilize sustainable basswood to preserve traditional carving techniques. Collectors in 2026 prioritize these items for their historical accuracy and their status as iconic pieces of outdoor heritage.

Physical Dimensions and Material Standards

Standard upright drake models follow precise dimensions of 17.875 inches in length and 7.375 inches in width. Professional grade equipment maintains a weight of 27.54 ounces to ensure realistic stability in various water conditions. Modern manufacturing processes use foam-filled EVA blends to create puncture-resistant shells that mimic the high-contrast profiles of original wooden carvings. These technical specifications allow the decoys to withstand heavy use while remaining visible to passing waterfowl from long distances.

Realistic vs. Rustic Finishes

Realistic finishes use UV-reflective paints and anatomical precision to mimic live birds, whereas rustic finishes highlight wood grain and weathered textures for an artisanal aesthetic. Choice depends on whether the user prioritizes field accuracy or interior design charm.

| Comparison Factor | Realistic Anatomical Finish | Traditional Rustic Finish |

|---|---|---|

| Primary Visual Goal | Biological accuracy and plumage mimicry | Vintage charm and hand-carved texture |

| Coating Technology | UV-reflective and iridescent pigments | Distressed stains and matte sealants |

| Material Application | High-density polymers or sealed wood | Sustainable basswood with exposed grain |

Aesthetic Traits of Anatomical and Weathered Designs

Realistic models emphasize feather detail and species-specific color patterns to ensure lifelike appearances. Collectors in 2026 favor hand-painted textures that provide depth beyond standard factory coatings, seeking out nuances that replicate the natural shift of light across a bird’s wing. These designs utilize anatomical precision to satisfy both high-end display requirements and practical field utility.

Rustic finishes rely on hand-carved imperfections and distressed stains to create a vintage or antique atmosphere. Artisanal designs often leave sections of sustainable basswood exposed to showcase natural wood grain, celebrating the material’s organic origin. This style prioritizes the creator’s touch, using weathered textures to evoke a sense of history and heritage in home décor settings.

Performance Metrics for Surface Coatings and Materials

UV-reflective coatings help decoys maintain visibility and realism by simulating natural waterfowl plumage. Manufacturers apply matte finishes to prevent unnatural glare, which remains a critical factor for professional displays and outdoor use. Iridescent paint elements further enhance this effect, providing tactile realism while increasing the decoy’s resistance to environmental fading.

High-density materials like basswood require precise humidity control to prevent paint chipping or wood cracking over time. Maintaining a stable environment protects the structural integrity of the carving and the longevity of the surface treatment. Flocked finishes offer an additional layer of protection and realism, serving as a durable barrier against the typical wear associated with frequent handling or seasonal temperature shifts.

Wood Selection for Decoys

Hand-carved decoys primarily utilize sustainable basswood and USA Eastern Pine due to their fine grain and structural integrity. While wood makes up less than 1% of the modern hunting market, these materials remain the standard for collectors in 2026 because they offer superior realism and durability compared to plastic alternatives.

Basswood and Eastern Pine Varieties

Artisans select sustainable basswood from primeval forests because of its uniform density and ability to hold intricate carving details. This wood variety allows for fine feather texturing and anatomical precision that often eludes softer or more porous timbers.

Traditional carvers favor USA Eastern Pine for standard decoys. Manufacturing specifications for these pieces typically target dimensions of approximately 13.5 inches long, 7.5 inches tall, and 6 inches deep to mimic the profile of native waterfowl. Pine provides a resilient base that accepts oil-based paints and sealants effectively.

High-density cork provides a heavy, premium alternative for specific hunting environments. Cork tracks realistically in rough water despite higher material costs, making it a functional choice for traditionalists. The material’s natural buoyancy helps the decoy maintain a lifelike posture even in choppy conditions.

Technical Durability and Weight Specifications

Production teams implement multi-stage humidity control during the curing phase to stabilize the wood. This technical step prevents the finished product from cracking or warping when exposed to extreme temperature shifts in the field.

Current factory standards for premium wooden decoys align with FSC and ISO 9001 certifications. These protocols guarantee the quality of the wood and the sustainable origin of all timber batches. Adherence to these standards ensures that the materials meet strict density and moisture content requirements for long-term use.

Premium Hand-Carved Wooden Ducks: Scalable Artistry for Your Brand

The Painting Process (Hand-Painted)

Artisans spend 40 to 75 hours painting each decoy, applying 5 to 7 layers of semi-translucent acrylic paint. They use micromotor tools for feather texturing and dry brushing for detail. Final steps involve using matt finishes and sun-baking the pieces to ensure the paint adheres firmly for 2026 standards.

Surface Texturing and Multi-Layer Pigmentation

The painting phase involves applying five to seven layers of semi-translucent acrylic paint. Using semi-translucent pigments instead of heavy, opaque coats keeps the carved wood textures visible and prevents the decoy from looking like plastic. This labor-intensive cycle often takes between 40 and 75 hours to complete for a single piece.

Complex species require careful planning to achieve professional realism. For birds with iridescent plumage, such as the Wood Duck, painters map out color zones before they begin blocking in colors. They identify the specific areas for greens, purples, and yellows to ensure the final transition looks seamless. This mapping prevents different pigments from becoming muddy during the layering process.

Technical Detailing and Finish Durability

Painters use dry brushing to create realistic shadows and soft feathered edges on the chest and body. By using a brush that is mostly dry, they can apply thin streaks of color that mimic the fine barbs of a real feather. This technique works best when layering lighter shades, like khaki or tan, over darker base coats to build contrast without harsh lines. To simulate the subtle sheen of iridescent feathers, artisans often add fine highlights using colored pencils directly over the dried acrylic base.

Durability depends on the selection of finishes and the curing process. Artisans choose matt or flat finishes like Resene Concrete Clear Flat to eliminate light reflection, as wild ducks rarely have shiny plumage. Once the painting is complete, they bake the decoys under the sun on hot days. This natural heat treatment cures the paint and ensures it adheres firmly to the wood, preventing the finish from rubbing off during handling or exposure to the elements.

Display Options (Mantel vs. Shelf)

Fireplace mantels offer deep 10-inch surfaces and lengths up to 96 inches, making them ideal for heavy, large-scale decoy scenes. Smaller wall shelves provide versatile, space-saving alternatives. Both options utilize hardwoods like Walnut and Red Oak, often relying on French cleat systems for secure, flush-to-wall mounting.

Structural Mantels for Large Scale Wetland Scenes

Standardized mantel lengths of 60, 72, and 84 inches provide ample space for complex, multi-bird arrangements. These dimensions allow for the creation of expansive wetland scenes that act as a primary focal point in a living space. Collectors can arrange several decoys alongside natural elements to replicate a full habitat without crowding the surface.

A 10-inch depth and 9.5-inch height accommodate the specific physical dimensions and weight of hand-carved basswood ducks. The deep profile supports the load of heavy carvings directly on the fireplace face, ensuring the birds remain secure while maintaining the visual proportions of the room architecture.

Hardwood Selection and Secure Mounting Specifications

Choosing high-quality wood species like Red Oak, Cherry, Walnut, and Mahogany ensures the display matches the artistic quality of the decoys. These hardwoods provide a stable foundation that resists wear and complements the traditional aesthetic of carved waterfowl. Custom lengths reaching up to 96 inches allow for displays that fit large-scale rooms while maintaining structural integrity.

French cleat installation systems provide the necessary load-bearing capacity to prevent the shelf from sagging over time. This mounting method distributes the weight of the decoys and the mantel shelf evenly against the wall studs. This creates a flush-to-wall fit that remains secure even when supporting a full collection of heavy wooden carvings.

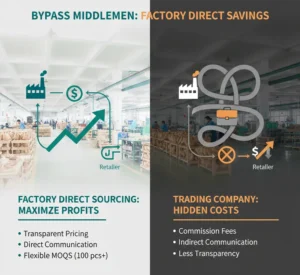

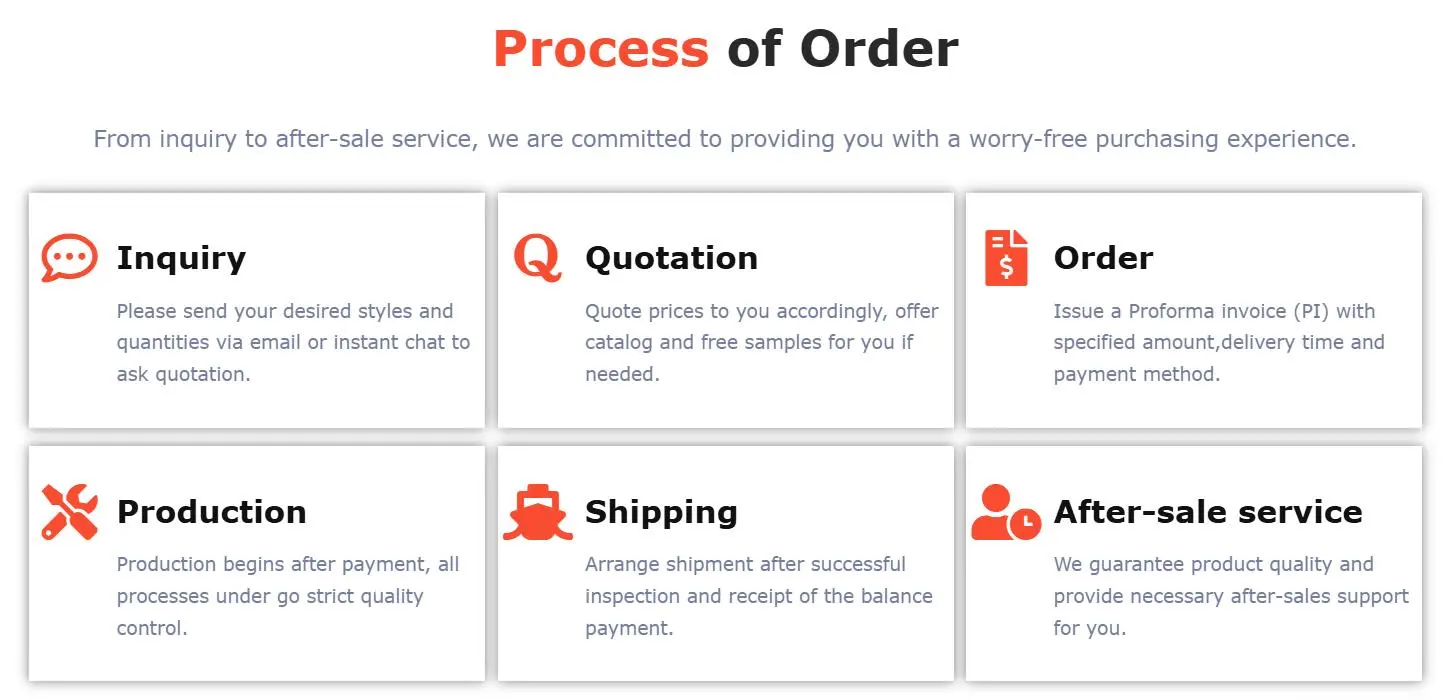

Wholesale Ordering Tips

Buyers in 2026 should focus on selecting durable woods like Atlantic White Cedar and Cypress. Success requires balancing a 300-piece minimum order quantity with custom design flexibility and verified quality control standards to meet global retail demands.

Material Standards and Customization Strategy

Professional buyers select materials like Atlantic White Cedar or Cypress to guarantee long-term durability and natural resistance to environmental decay. These wood types offer the essential structural integrity needed for hand-carved products. We recommend sourcing decoys finished with UV-resistant, non-peeling paint to prevent surface glare and maintain aesthetic quality in retail displays.

Customization through OEM capabilities allows buyers to adapt product dimensions to specific regional bird species. While standard decoys often measure between 11.5 and 12.75 inches, adjusting the size and weight helps meet local consumer preferences. Incorporating features like forward-weighted keels or foam-filled interiors improves flotation stability, adding technical value to the final product.

Order Logistics and Quality Compliance

Volume orders for custom shapes or specialized packaging usually require a minimum order quantity of 300 pieces. This threshold ensures manufacturing efficiency while allowing for unique design variations. Buyers must require FSC and ISO 9001 certifications from suppliers to confirm sustainable sourcing and rigorous quality consistency across large production runs.

Structuring payments with a 30% initial deposit protects the production timeline. Choosing Incoterms like FOB or DDP clarifies shipping responsibilities and helps manage international logistics costs effectively. Environmental controls also play a role in bulk storage; maintaining relative humidity between 40% and 60% prevents wood shrinkage and protects the integrity of the paint finish during transit and warehousing.

Final Thoughts

Selecting a decoy depends on whether the user seeks field performance or home aesthetics. Realistic models provide the anatomical accuracy needed for professional displays, while rustic designs offer a weathered charm that highlights the natural wood grain. Both styles preserve a carving tradition that transforms sustainable timber into functional art.

Frequently Asked Questions

Where can I source vintage-style wooden decoys?

Specialty retailers like Muddy Water Decoys provide authentic and reproduction pieces with entry prices starting around $200. Online marketplaces such as Etsy and Solis Depot offer hand-carved options. The Minnesota Decoy Wood Carvers Club provides resources for those seeking custom antiqued replicas.

What is the price difference between rough and fine finishes?

Market data shows a significant price gap based on the level of detail. Rough-cut display stands typically cost $9.00. Finished vintage working decoys sell for approximately $52.26, representing a $43.26 premium for the fine-carving and painting required for field use.

Are unpainted decoy blanks available for custom projects?

Yes, several manufacturers supply unfinished blanks. Dux’ Dekes offers Eastern white pine options for $24.00. Meyers Classic Decoys provides unpainted kits for species like Mallards and Canvasbacks ranging from $80.00 to $150.00 per dozen.

Can wooden decoys withstand outdoor hunting conditions?

Wooden decoys handle rough water and freezing temperatures effectively. They require proper storage to prevent paint degradation. In the 2026 market, many hunters also utilize foam-filled alternatives which offer enhanced durability against shot damage during heavy field use.

How accurately can carvers replicate specific duck breeds?

High-fidelity replicas use precise measurements derived from species like the mallard (Anas platyrhynchos). These are artistic approximations. Manufacturers utilize genomic trait mapping, with contig N50 lengths of 4.68 Mb, to ensure visual accuracy across various breeds.

How does the manufacturing process ensure consistent quality?

Quality control involves a multi-stage framework focusing on material integrity. Jilin Ever Creation monitors wood humidity levels and inspects every semi-finished piece to ensure all items meet international durability standards for the 2026 export market.