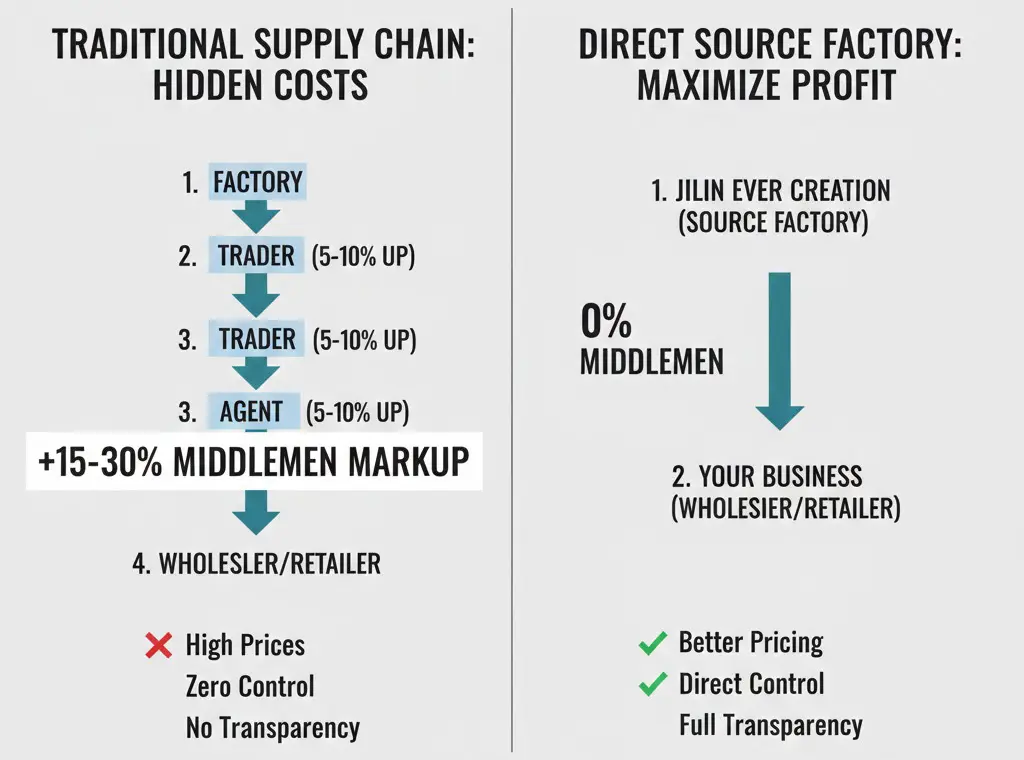

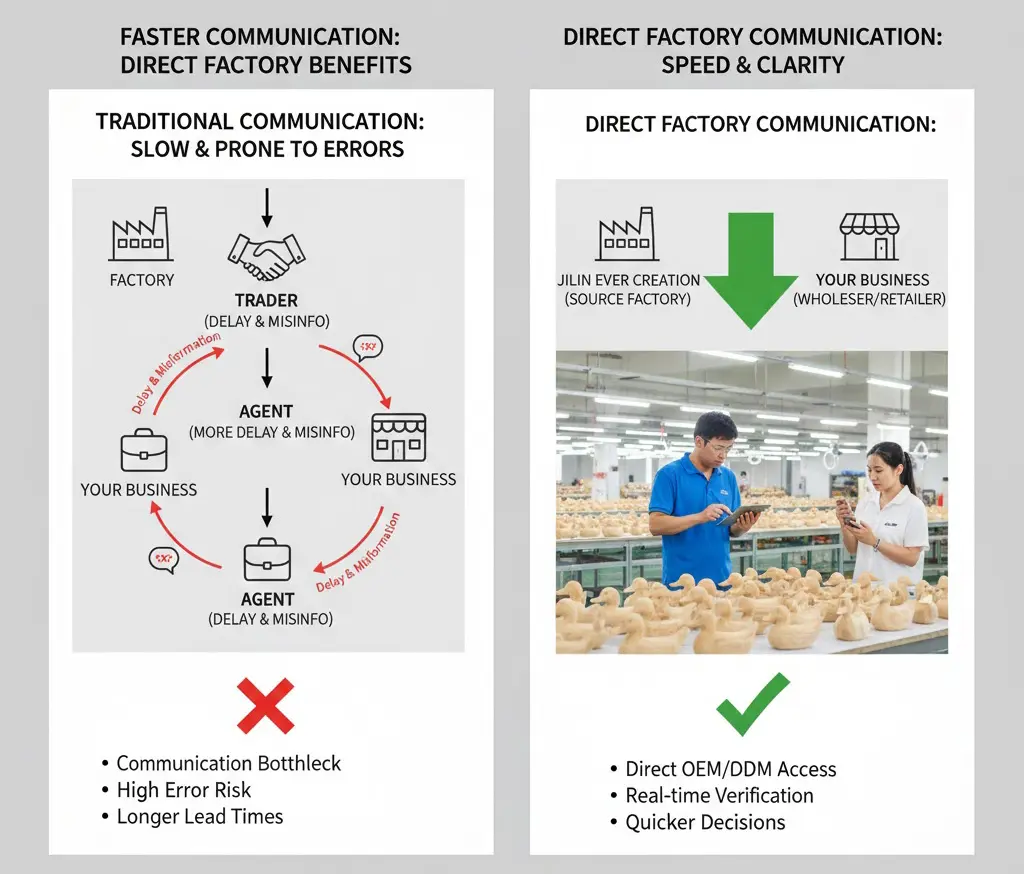

Factory Direct Sourcing directly attacks the 15-30% margin stack added by traders and sourcing agents. A layered supply chain doesn’t just inflate your unit cost; its communication delays and misinterpretations lead to production errors that damage your profit and timelines.

This analysis provides a framework for connecting with a source factory in Jilin. We cover how to secure direct T/T 30/70 payment terms, verify operations via video call, and structure sea freight shipments to eliminate hidden fees and gain full supply chain control.

Supply Chain Structure

Working directly with a source factory like Jilin Ever Creation cuts the 15-30% in middlemen markups, giving you better pricing, direct control, and real supply chain transparency.

The Hidden Costs of Middlemen

Conventional supply chains are layered. A product moves from the factory to traders, then agents, and finally to you. Each one of these intermediaries adds their own margin to the price. This “margin stack” is not a small fee—it routinely inflates your final cost by 15-30% over the actual factory price.

This structure doesn’t just hurt your bottom line. It also creates a communication bottleneck. When you need an update on production or want to verify quality control, your questions get filtered through multiple parties. You lose visibility and control over the process.

Our B2B Source Factory Advantage

We operate as a B2B Manufacturer, a source factory serving dealers, wholesalers, and brand owners directly. There are no traders or agents between us and our partners. This model provides genuine ‘Source-to-Shelf Integrity,’ which means you get clear communication and no hidden fees.

Working with us directly gives you tangible benefits:

- Direct OEM/ODM Access: You communicate your customization needs straight to the people who will build your product.

- Rigorous Quality Control: You have a direct line of sight into our quality standards and processes, without any third-party filtering information.

- Optimized Logistics: We structure larger wholesale orders for sea freight to maximize your profit margins.

Jilin Carving Heritage

Jilin’s carving heritage combines traditional artisan skills with modern manufacturing, providing a foundation for handcrafted goods that blend historical techniques with consistent quality for global markets.

A Legacy of Craftsmanship and Production

Jilin province is a well-established regional hub that combines traditional wood carving craftsmanship with modern manufacturing. The area has a long history of woodworking, supported by local resources like the premium Basswood and Pine from the Changbai Mountains.

The region’s heritage is built on ancient art forms like ‘pit carving’ (hediao), an intricate skill recognized as a National Intangible Cultural Heritage. This deep cultural foundation provides a pool of highly skilled artisans and established production knowledge that directly informs our modern operations.

Time-Honored Techniques in Every Piece

Our artisans apply these time-honored techniques to every wooden duck we produce, ensuring each one has a hand-sculpted authenticity. This commitment to manual skill means our products are born from wood and expertise, not from automated machines.

This process naturally creates “Artisanal Variance”—slight variations in grain, posture, or paint strokes. These are not defects; they are the hallmarks of authentic, handcrafted goods that make every piece one-of-a-kind. The result is a fusion of regional legacy and our own Master Craftsmanship, creating uniquely detailed products you can trust.

Elevate Your Inventory with Handcrafted Ducks

Cost Breakdown (-30%)

Sourcing directly from the factory eliminates trader markups (10-20%) and agent commissions (3-5%). This streamlined supply chain cuts product costs and optimizes logistics, driving total savings around 30%.

| Cost Layer (Eliminated) | Typical Markup in Traditional Models |

|---|---|

| Trader Markup | 10-20% added to factory cost |

| Sourcing Agent Commission | 3-5% on top of product price |

| Hidden Coordination Fees | Variable charges for handling & documentation |

Identifying and Removing Intermediary Markups

The traditional import model involves a “margin stack,” where each middleman adds their own layer of cost. When you source directly from a factory like us, you bypass these intermediaries and their associated fees. This is where the bulk of the savings comes from.

- Trader Markup: This is the largest cut. Trading companies typically add a 10-20% markup on the factory’s base price. We eliminate this completely.

- Sourcing Agent Commission: Agents charge a separate 3-5% commission just for connecting you to a trader or factory. Working directly with us removes this fee.

- Hidden Fees: Costs for extra handling, redundant documentation, and coordination between multiple parties add up. A direct relationship simplifies this, cutting out unnecessary charges.

Direct Commercial Terms that Protect Your Margins

True cost savings go beyond the unit price. Dealing directly with the source gives you control over logistics and payment structures that are designed to protect your bottom line, not a middleman’s.

- Optimized Sea Freight: For wholesale orders with a Minimum Order Amount (MOA) of $3,000, we use sea freight. This method is designed to maximize your profit margins on larger volumes.

- Transparent Payment Terms: Our standard terms are a T/T 30% deposit and 70% balance. We send high-resolution photos and videos of your finished goods for verification before you pay the final balance, protecting your cash flow.

- Hassle-Free Trial Orders: For initial orders, we use DDP (Delivered Duty Paid) air express shipping. This means we handle all customs and delivery fees, so the price you’re quoted is the price you pay, delivered to your door.

Faster Communication

Working directly with the factory eliminates intermediaries. This means clearer, faster exchanges that reduce errors, speed up decisions, and get your product to market faster.

Reducing Errors and Lead Times

When you talk directly with factory staff, your requirements get translated correctly the first time. There’s no game of telephone where a trading company or agent might misinterpret technical details. This direct line dramatically cuts down on manufacturing errors. Feedback loops are also much quicker. Instead of waiting for a message to pass through multiple parties, you get answers and adjustments made immediately, which shortens your overall lead time.

Verification Before Final Payment

We use direct communication to protect your cash flow. Before the 70% balance payment is due, our team provides high-resolution photos and videos of your finished goods. You see exactly what you’re getting before the final wire transfer. This step removes uncertainty and ensures you have full confidence in the product quality, so you aren’t paying the bulk of the cost for something you haven’t approved.

English Capabilities

Clear English communication stops manufacturing errors and logistical headaches. Our English-proficient teams manage everything from custom specs to shipping documents, ensuring global partners get exactly what they ordered.

Why English Proficiency is Critical for Importers

When you’re sourcing custom products, “good enough” English from a supplier is a major liability. A single misunderstood detail about materials, dimensions, or packaging can ruin an entire production run, costing you thousands. The risk doesn’t end at the factory floor.

Inaccurate logistics documentation, from shipping marks to customs declarations, can get your shipment flagged, delayed, or even rejected by authorities in the EU and USA. Clear, precise communication is non-negotiable for smooth international trade.

Fluent Support from Product Design to Delivery

We eliminate communication barriers entirely. For complex OEM/ODM projects, you work directly with our English-speaking sales and R&D teams who understand the technical details. There are no layers of translation to create confusion.

You receive all documentation in clear, professional English. This includes proforma invoices, technical sheets, and internationally recognized compliance certificates like FSC, BSCI, and EN71. We ensure every piece of paperwork is accurate so your focus stays on your business, not on solving avoidable problems.

Verification (Video Call)

Video call verification lets you remotely inspect our factory, production, and finished goods. This transparency builds trust and secures your investment before you pay the final balance.

Confirming Operations with Real-Time Views

A live video call cuts through the uncertainty of sourcing. It allows you to see our factory floor, artisan workshops, and active production lines without needing to travel. You can assess our scale and operational capacity firsthand. This isn’t about a polished corporate video; it’s a real-time view that builds genuine confidence in our ability to deliver before you place an order.

Pre-Shipment Verification for Quality Assurance

We use video to protect your cash flow. Once your order is complete, we provide high-resolution photos and videos of the finished goods for your approval. This process ensures every detail meets your specifications and our handcrafted quality standards. This verification happens *before* the final 70% balance payment is due, completely removing the risk of paying for products that don’t meet your expectations.

Transitioning Suppliers

Shifting from wholesalers to a direct factory eliminates 15-30% in markups and increases supply chain control. Our low-MOQ trial order program simplifies this transition.

Key Benefits of Sourcing Directly from the Factory

Working through layers of traders and agents creates a “margin stack” that inflates your costs before goods even leave the port. Going direct dismantles this structure, giving you immediate financial and operational advantages.

- Recapture Lost Margin: You immediately eliminate trader markups and agent commissions, which typically add 15-30% to the factory price. This saving goes directly back to your bottom line.

- Gain Supply Chain Control: Get real-time visibility into production schedules and capacity. Direct oversight of quality control at the factory level reduces defects and costly returns discovered after delivery.

- Improve Response Times: Communicate directly with the production team to resolve issues or make specification changes quickly, without the delays caused by messages passing through intermediaries.

A Low-Risk Path to Transition: Our Trial Order Program

We built a specific program to help businesses move their sourcing to us without the risk of large volume commitments. It’s designed to be a simple, straightforward test of our products and process.

- Low Initial Commitment: Start with a Minimum Order Quantity (MOQ) of just 100 pieces and a Minimum Order Amount (MOA) of USD $500 from our in-stock inventory.

- Hassle-Free Logistics: We ship trial orders via DDP (Delivered Duty Paid) air express. This means we handle all customs, duties, and logistics, delivering directly to your door with no hidden fees.

Frequently Asked Questions

What is the difference between a factory and a trading company?

A factory, like us, manufactures products directly. We control the entire process from raw material sourcing to final production. A trading company is an intermediary that buys finished goods from various factories and sells them. Sourcing from a factory ensures better quality control, direct communication, and avoids middleman costs.

Can I visit your factory in person?

Yes, we welcome and encourage factory visits. Arranging a visit allows you to see our craftsmanship firsthand, meet the team, and verify our quality control processes. Please contact us to schedule a time so we can ensure our team is available to host you.

Where is your factory located?

Our facility is in Jilin, a province in Northeast China. This region is home to the Changbai Mountains, which is where we ethically source the premium Basswood and Pinewood for our wooden carvings, giving us direct access to high-quality materials.

Is communication in English an issue?

No, our dedicated sales and support teams are proficient in English and experienced in working with international clients. We recommend using written communication like email for detailed specifications to ensure all technical details are clearly understood by our production team.

Final Thoughts

Sourcing through traders presents a false economy, hiding 15-30% in markups while introducing supply chain risk. Our direct model provides Source-to-Shelf Integrity, protecting your brand from the quality failures and communication blackouts common with middlemen. This approach builds a reliable supply partnership, not just a one-time transaction.

Verify our craftsmanship and process for yourself. Our DDP trial order program is the most direct way to test our Hand-sculpted Authenticity with zero logistical headaches. Contact our team to secure a trial shipment or to discuss your custom OEM requirements.

While looking for specific styles, don’t forget to check our full catalog of [Wholesale Wooden Ducks] to see all available options.

We don’t just make ducks. As a comprehensive [Wooden Bird Factory], we also produce cardinals, owls, and robins.